If you are looking to unleash the power of advanced materials, look no further than the fused silica crucible. This specially designed container is capable of withstanding incredibly high temperatures and is used in a variety of applications, from the manufacturing of complex diamond-based composite structures to the production of elemental Te in tellurite glass systems.

The fused silica crucible is made from a form of silica glass that has been melted and then re-solidified to create a highly durable, heat-resistant material. Because of its unique properties, it is able to withstand temperatures of up to 1,800 degrees Celsius, making it an ideal choice for a wide range of high-temperature applications.

In addition to its high-temperature resistance, the fused silica crucible is also highly resistant to chemical corrosion and is able to maintain its structural integrity even when exposed to harsh chemicals. This makes it an ideal choice for use in the production of a wide range of advanced materials, from semiconductors to ceramics and beyond.

Understanding Fused Silica Crucibles

If you work with advanced materials, you know how important it is to have the right equipment. Fused silica crucibles are a popular choice for many applications due to their high purity and resistance to thermal shock. In this section, we’ll take a closer look at fused silica crucibles and what makes them so special.

Composition and Properties

Fused silica crucibles are made from pure, amorphous silica. This material is created by melting high-purity silica sand at extremely high temperatures and then cooling it rapidly to prevent crystallization. The resulting material is a highly pure, transparent, and extremely hard substance.

One of the key properties of fused silica crucibles is their ability to withstand high temperatures. They can typically be used at temperatures up to 1,800°C without cracking or breaking. Additionally, fused silica crucibles have a low thermal expansion coefficient, which means they do not expand or contract significantly when exposed to temperature changes. This makes them ideal for use in applications where temperature stability is critical.

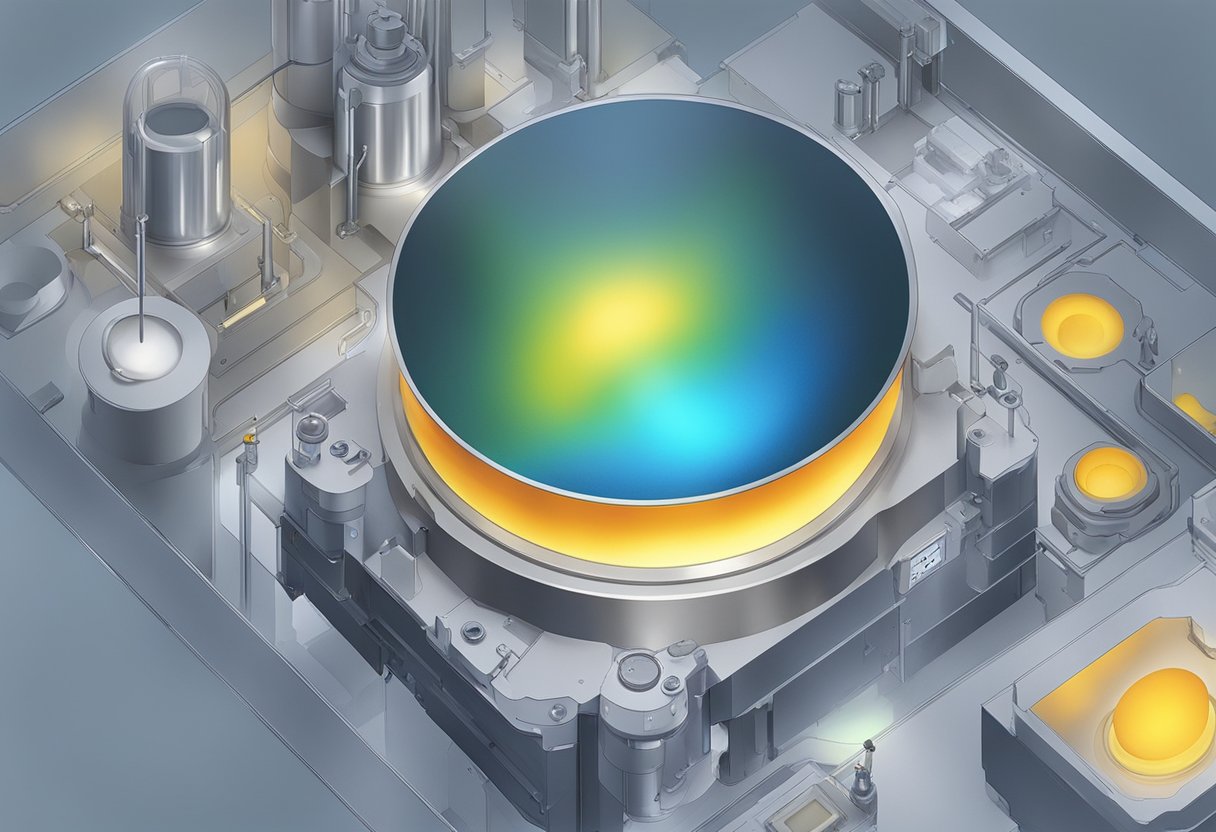

Manufacturing Process

The manufacturing process for fused silica crucibles is complex and requires specialized equipment and expertise. The process begins with high-purity silica sand, which is melted in a furnace at temperatures exceeding 2,000°C. The molten silica is then poured into molds and allowed to cool slowly over a period of several days. The resulting crucibles are then carefully inspected and tested to ensure they meet strict quality standards.

Types and Variations

Fused silica crucibles come in a variety of shapes and sizes, including cylindrical, conical, and rectangular. They can also be customized to meet specific application requirements. For example, some fused silica crucibles are designed with a tapered bottom to make it easier to pour out the contents. Others are coated with a layer of platinum to provide additional protection against chemical reactions.

In addition to standard fused silica crucibles, there are also variations designed for specific applications. For example, some crucibles are designed for use in semiconductor manufacturing, while others are optimized for use in the production of optical components. These specialized crucibles may have unique shapes, coatings, or other features that make them better suited for their intended use.

Overall, fused silica crucibles are an excellent choice for applications that require high purity, thermal stability, and resistance to thermal shock. Whether you’re working in the semiconductor industry, producing optical components, or conducting research in materials science, fused silica crucibles are an essential tool in your arsenal.

Applications in Advanced Materials

Fused Silica Crucible is a versatile material that can be used in various applications in the field of advanced materials. Here are some of the applications where Fused Silica Crucible can be used:

High-Temperature Processes

Fused Silica Crucible can withstand high temperatures, making it an ideal material for use in high-temperature processes. It can be used in the production of advanced materials such as ceramics and semiconductors. The material’s high-temperature resistance makes it suitable for use in the manufacturing of high-temperature furnaces, where it can be used as a container for molten materials.

Chemical Resistance Applications

Fused Silica Crucible is chemically inert, which makes it resistant to chemical reactions. It can be used in chemical applications where it is important to maintain the purity of the materials being processed. The material’s chemical resistance also makes it suitable for use in the production of high-purity chemicals and pharmaceuticals.

Precision Casting

Fused Silica Crucible is also used in precision casting applications, where it is used to create complex shapes with high precision. The material’s high-temperature resistance and chemical inertness make it an ideal material for use in precision casting applications. It can be used to create parts for aerospace, medical, and industrial applications.

In conclusion, Fused Silica Crucible is a versatile material that can be used in various applications in the field of advanced materials. Its high-temperature resistance, chemical inertness, and precision casting capabilities make it an ideal material for use in the production of advanced materials such as ceramics, semiconductors, high-purity chemicals, and pharmaceuticals.

Advantages of Using Fused Silica

When it comes to choosing a crucible for your laboratory, one material stands out above the rest: Fused Silica. Fused Silica Crucibles have many advantages over other materials, making them the go-to choice for many scientists and researchers.

Thermal Stability

Fused Silica Crucibles are known for their excellent thermal stability. They can withstand high temperatures without cracking or deforming, making them ideal for use in high-temperature applications. This thermal stability also makes them ideal for use in rapid thermal processing (RTP) applications, where the crucible is exposed to rapid temperature changes.

Durability

Fused Silica Crucibles are also incredibly durable. They are resistant to thermal shock, which means they can withstand sudden changes in temperature without cracking or breaking. They are also resistant to chemical corrosion, making them ideal for use with corrosive materials.

Purity

Fused Silica Crucibles are made from high-purity silica, which means they are free from impurities that can contaminate your samples. This purity makes them ideal for use in applications where sample purity is critical, such as in the semiconductor industry.

In addition to these advantages, Fused Silica Crucibles are also easy to clean and maintain, which can save you time and money in the long run. Overall, Fused Silica Crucibles are an excellent choice for any laboratory that requires a high-quality crucible for their research.

Considerations for Handling and Maintenance

When it comes to handling and maintaining Fused Silica Crucibles, there are several important factors to keep in mind. These crucibles are made from advanced materials and can be used for a variety of applications, including thermal management and sensor development. To ensure their longevity and effectiveness, it is important to follow proper handling and maintenance procedures.

Cleaning and Storage

Cleaning and storage are critical considerations when it comes to Fused Silica Crucibles. These crucibles should be cleaned thoroughly after each use to prevent any residual material from contaminating future experiments. A soft-bristled brush and mild detergent can be used to clean the crucible. Avoid using any abrasive materials that could scratch the surface of the crucible.

After cleaning, the crucible should be stored in a clean, dry environment to prevent any damage or contamination. It is recommended to store the crucible in a protective case or container to prevent it from being damaged during storage or transportation.

Usage Guidelines

When using Fused Silica Crucibles, it is important to follow proper usage guidelines to prevent any damage or contamination. These crucibles should be handled with care and never dropped or mishandled. It is also important to avoid overloading the crucible, as this can cause it to crack or break.

It is recommended to preheat the crucible before use to prevent thermal shock and ensure even heating. When using the crucible, it is important to monitor the temperature to prevent overheating or thermal damage.

Lifecycle and Recycling

Fused Silica Crucibles have a long lifecycle and can be recycled at the end of their useful life. It is important to dispose of used crucibles properly to prevent any environmental damage. Many recycling facilities accept Fused Silica Crucibles for recycling, and some manufacturers offer recycling programs for their products.

In conclusion, proper handling and maintenance of Fused Silica Crucibles is essential to ensure their longevity and effectiveness. By following these guidelines, you can ensure that your crucibles remain in good condition and provide reliable performance for your experiments and applications.

Innovations and Future Outlook

As technological advancements continue to take place, the future of Fused Silica Crucible looks bright. The use of advanced materials has revolutionized the manufacturing industry, and Fused Silica Crucibles are no exception. With their superior thermal shock resistance and high purity, Fused Silica Crucibles have become the crucible of choice for high-temperature applications.

Technological Advancements

The development of Fused Silica Crucibles has been driven by the need for higher purity and better thermal shock resistance. With the advent of advanced manufacturing techniques, it is now possible to produce Fused Silica Crucibles with even higher purity and better thermal shock resistance. This has led to an increase in demand for Fused Silica Crucibles in a wide range of industries, including the semiconductor, solar, and optical industries.

The use of advanced materials in the manufacturing of Fused Silica Crucibles has also led to the development of new manufacturing processes. For example, the use of spark plasma sintering has been shown to be an effective method of producing Fused Silica Crucibles with high purity and excellent thermal shock resistance.

Emerging Markets

As emerging markets continue to grow, the demand for Fused Silica Crucibles is expected to increase. This is particularly true in the semiconductor industry, where the demand for Fused Silica Crucibles is driven by the need for high-purity materials for use in the production of microchips.

In addition, the solar industry is also expected to drive demand for Fused Silica Crucibles. Fused Silica Crucibles are used in the production of solar cells, where their high purity and excellent thermal shock resistance make them an ideal material for use in high-temperature applications.

Overall, the future of Fused Silica Crucibles looks bright. With the continued development of advanced materials and manufacturing techniques, the demand for Fused Silica Crucibles is expected to increase in a wide range of industries.

Post time: 12 月-18-2023