Advanced materials, precision engineering, and customized solutions are the hallmarks of today’s high-tech world. One such material that has gained immense importance is Customized Silica Fused Quartz Glass. This remarkable material finds applications in various industries, from electronics and photonics to semiconductors and optics. In this blog, we’ll explore the significance of Customized Silica Fused Quartz Glass and delve into key aspects like its thermal properties and how to choose the right supplier. Let’s embark on a journey into the world of this unique material.

Customized Silica Fused Quartz Glass: An Overview

Silica Fused Quartz Glass, also known as fused silica or fused quartz, is a high-purity glass made primarily from silicon dioxide (SiO2). It exhibits exceptional thermal and optical properties, making it indispensable in numerous industries. However, what sets customized silica fused quartz glass apart is its tailored composition and properties to meet specific industrial requirements. These tailored solutions can range from custom shapes and sizes to precise thermal characteristics, ensuring they align perfectly with the intended application.

How to Choose the Right Customized Silica Fused Quartz Glass Supplier?

Selecting the right supplier for customized silica fused quartz glass is a crucial decision. The right supplier can make all the difference in terms of quality, performance, and cost-effectiveness. One such trusted manufacturer in the industry is Kamroller Special Ceramics Co., Ltd. Kamroller has established itself as a reputable provider of customized silica fused quartz glass, known for its commitment to precision and excellence.

When choosing a supplier, consider the following factors:

1. Expertise and Experience: Look for a supplier with a proven track record in the industry. Kamroller, for example, has decades of experience in manufacturing and customizing silica fused quartz glass for various applications.

2. Quality Assurance: Ensure the supplier adheres to strict quality control standards. Kamroller maintains rigorous quality checks throughout the production process to deliver products of the highest quality.

3. Customization Options: Evaluate the supplier’s ability to provide tailored solutions. Kamroller specializes in creating customized silica fused quartz glass products to meet unique specifications.

4. Material Purity: The purity of the material is crucial for demanding applications. Kamroller’s silica fused quartz glass boasts exceptional purity, ensuring optimal performance.

5. Timely Delivery: Reliable suppliers like Kamroller are known for their on-time deliveries, reducing downtime for your projects.

Customized Silica Fused Quartz Glass: What Are Its Thermal Properties?

The thermal properties of customized silica fused quartz glass are a significant consideration for many applications, especially those involving high-temperature environments. Fused quartz glass offers exceptional thermal stability, low thermal expansion, and high resistance to thermal shock. These properties make it ideal for use in industries such as semiconductor manufacturing, where precise control of temperature is critical.

1. Low Thermal Expansion: Customized silica fused quartz glass has a very low coefficient of thermal expansion, meaning it expands or contracts minimally with temperature changes. This property ensures dimensional stability in high-temperature environments.

2. High Softening Point: Fused quartz glass has a high softening point, typically exceeding 1,700 degrees Celsius. This enables it to withstand extreme temperatures without deforming or losing its structural integrity.

3. Thermal Shock Resistance: Silica fused quartz glass is known for its exceptional resistance to thermal shock. It can rapidly transition between hot and cold conditions without cracking or breaking, making it ideal for applications requiring rapid temperature changes.

4. Thermal Insulation: Customized silica fused quartz glass is an excellent thermal insulator, making it valuable in applications where heat needs to be controlled or contained effectively.

Customized Silica Fused Quartz Glass for Photonics: Why It Matters

The field of photonics, which involves the generation, manipulation, and detection of light, relies heavily on high-quality optical materials. Customized silica fused quartz glass plays a pivotal role in photonics applications due to its remarkable optical properties. It offers low optical absorption, high transparency in the UV, visible, and near-infrared spectra, and exceptional homogeneity.

In photonics, precision is paramount, and any compromise on the quality of optical components can result in significant performance degradation. Customized silica fused quartz glass ensures that optical components are tailored to meet the exact specifications required for specific photonics applications, such as laser systems, fiber optics, and imaging devices.

Furthermore, the low thermal expansion and excellent thermal stability of customized silica fused quartz glass are crucial in maintaining optical alignment and performance in photonics systems subjected to varying temperatures.

Customized Silica Fused Quartz Glass: Elevating Glass Bending with Fused Silica Ceramic Molds

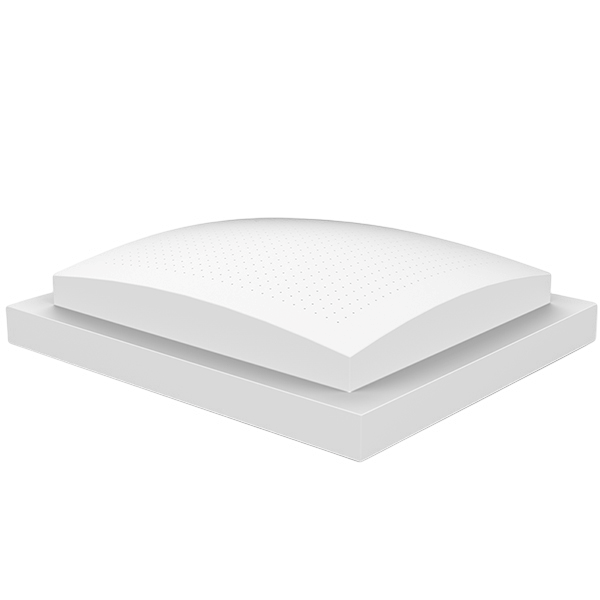

1. Crafting with Precision: The Fused Silica Ceramic Mold

For glass artists, professionals in the glassworking industry, and manufacturing facilities specializing in glass bending, precision is paramount. Achieving flawless and intricate glass bends demands the right tools, and one such indispensable tool is the Fused Silica Ceramic Mold. Crafted with meticulous precision and utilizing advanced materials, this mold is designed to elevate your craft and production capabilities to new heights.

2. The Power of Fused Silica Ceramic

At the heart of this remarkable mold is high-quality fused silica, a premium material renowned for its exceptional thermal stability, low thermal expansion, and superb resistance to high temperatures. These properties ensure that the mold can withstand the harsh conditions of glass bending processes, retaining its structural integrity and shape even through countless heating and cooling cycles.

The fusion of precision engineering and top-notch materials results in a mold that is not only durable but also highly efficient in delivering consistent and high-quality glass bends.

3. Precision Meets Ergonomics

The Fused Silica Ceramic Mold boasts a sleek and ergonomic design that facilitates easy handling and maneuverability. Its smooth, non-porous surface minimizes the risk of glass sticking, ensuring clean and flawless bends every time. The precise dimensions and contours of the mold enable glass artisans and professionals to exercise precise control over the glass shaping process, allowing for the creation of intricate and customized designs with ease.

4. Unmatched Heat Resistance

One of the standout features of our Fused Silica Mold is its exceptional heat resistance. It can withstand temperatures of up to [insert temperature], making it suitable for a wide range of glass bending techniques. Whether you’re slumping, sagging, or forming complex curves, this mold is up to the task. Its remarkable durability allows for prolonged use without compromising its performance, making it a cost-effective solution for glass bending operations.

5. Customization for Your Unique Needs

Glass bending comes in various shapes and sizes, and that’s why our Fused Silica Ceramic Mold is customizable to meet your specific requirements. Whether you need a particular size, shape, or design, we can tailor the mold to suit your unique needs. This flexibility ensures that you have the perfect tool in hand for your glass bending projects, no matter how intricate or challenging they may be.

6. Applications and Benefits

The usage of a Fused Silica Ceramic Mold for glass bending is essential in various glassworking applications. It provides artisans and professionals with the means to shape glass into precise curves, angles, or forms, allowing for the creation of stunning and customized glass pieces. Whether you’re producing functional glassware or decorative art, this mold ensures that your glass bends are of the highest quality.

Conclusion

Customized Silica Fused Quartz Glass is a versatile and invaluable material for various industries. When tailored to specific requirements, it can unlock new possibilities in engineering and technology. Choosing the right supplier, such as Kamroller Special Ceramics Co., Ltd., is essential for obtaining the highest quality customized silica fused quartz glass. Its remarkable thermal properties and optical excellence make it a cornerstone in industries like photonics, ensuring precision and reliability in critical applications. When it comes to custom solutions, the investment in customized silica fused quartz glass is undoubtedly worth it.

Post time: 12 月-12-2023