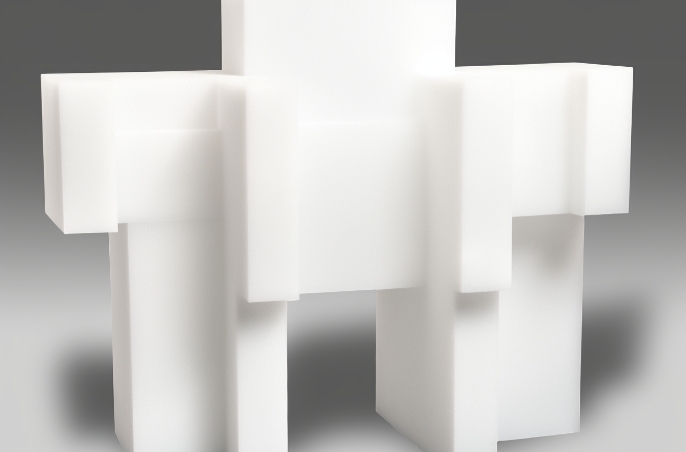

When it comes to high-temperature applications that demand exceptional thermal stability, low thermal expansion, and resistance to chemical corrosion, fused silica bricks are the go-to choice. These specialized refractory bricks, primarily composed of fused silica or amorphous silicon dioxide (SiO₂), find their way into various industries such as glass manufacturing, ceramics, metal casting, and petrochemicals. In this blog, we will explore the characteristics and applications of fused silica bricks, focusing on one of the leading Fused Silica Brick Suppliers and Manufacturers in the field, Kamroller Special Ceramics Co., Ltd.

Can Fused Silica Brick Suppliers and Manufacturers Meet Your Custom Requirements?

When businesses seek refractory materials for their high-temperature applications, customization often becomes a crucial consideration. Fused silica brick suppliers and manufacturers, including Kamroller Special Ceramics Co., Ltd., understand the importance of meeting custom requirements. These companies invest in research, technology, and production capabilities to ensure they can provide tailored solutions that align with the unique needs of their customers.

Customization in fused silica bricks can encompass various aspects, such as size, shape, chemical composition, and thermal properties. Whether you require bricks for glass manufacturing, ceramics, metal casting, or other industries, leading suppliers and manufacturers like Kamroller Special Ceramics Co., Ltd. have the expertise to deliver bespoke solutions that optimize performance and efficiency in your specific application.

Who Are the Leading Fused Silica Brick Suppliers and Manufacturers?

In the competitive world of fused silica brick production, certain names rise to the top, and Kamroller Special Ceramics Co., Ltd. is undeniably one of them. Established in 2006 through a partnership between KAMROLLER® and China Tianhong Hi-Tech Industrial Ceramics Co., Ltd., this company has garnered recognition as the largest production base of fused silica products in Asia.

KAMROLLER, a global leader in high-tech ceramics since 1988, has brought its wealth of knowledge and technological expertise to this collaboration. With manufacturing facilities and institutions in both the United States and China, these industry giants combine forces to provide top-quality products and services to customers worldwide.

What Sets Fused Silica Brick Suppliers and Manufacturers Apart?

The quality and reliability of fused silica bricks depend on the expertise and capabilities of the suppliers and manufacturers. What sets leading Fused Silica Brick Suppliers and Manufacturers like Kamroller Special Ceramics Co., Ltd. apart from the competition is their commitment to excellence, state-of-the-art facilities, and a deep understanding of the unique properties of fused silica.

These companies invest in cutting-edge technology, research and development, and quality control processes to ensure that their fused silica bricks meet the highest standards. Additionally, their ability to offer custom solutions tailored to specific industry needs is a significant advantage. Whether you require bricks with superior thermal stability for glass manufacturing or chemical-resistant bricks for petrochemical applications, these suppliers and manufacturers have the knowledge and resources to deliver.

Where Can You Find Reliable Fused Silica Brick Suppliers and Manufacturers?

Finding reliable fused silica brick suppliers and manufacturers is crucial for businesses in need of high-performance refractory materials. Fortunately, reputable companies like Kamroller Special Ceramics Co., Ltd. are accessible to meet your needs.

Here are some steps to consider when searching for reliable fused silica brick suppliers and manufacturers:

1. Online Research: Start by conducting online research to identify potential suppliers and manufacturers. Visit their websites to learn more about their products, services, and capabilities.

2. Industry Reputation: Look for companies with a strong reputation in the industry. Customer reviews, testimonials, and references can provide valuable insights into their track record and customer satisfaction.

3. Quality Assurance: Inquire about the quality control measures in place during the manufacturing process. Reliable suppliers should be able to provide certifications and assurances regarding the quality of their fused silica bricks.

4. Customization Options: If you have specific requirements, contact the supplier or manufacturer to discuss customization options. Leading companies like Kamroller Special Ceramics Co., Ltd. should be willing to work with you to meet your unique needs.

5. Communication: Effective communication is key when working with suppliers. Ensure that the company is responsive and can address your inquiries and concerns promptly.

6. Cost and Value: While cost is a factor, consider the overall value offered by the supplier or manufacturer. High-quality products may come with a slightly higher price tag but can provide long-term benefits in terms of performance and durability.

Fused Silica Bricks: Unveiling Their Characteristics

Fused silica bricks are renowned for their remarkable properties, making them indispensable in high-temperature settings. Here are some key characteristics that set them apart:

1. High Thermal Stability: Fused silica bricks exhibit exceptional resistance to rapid temperature changes, commonly referred to as thermal shocks. Even in the most demanding environments, these bricks remain intact without cracking or breaking.

2. Low Thermal Expansion: One of the standout features of fused silica is its incredibly low coefficient of thermal expansion. This means that as these bricks are exposed to temperature variations, they undergo minimal expansion or contraction, reducing structural stresses and ensuring longevity.

3. Chemical Inertness: Fused silica is highly resistant to both acidic and basic environments. This property is invaluable in industries where exposure to corrosive substances is common, making these bricks suitable for a wide range of chemical processing applications.

4. Optical Properties: While not their primary function, fused silica bricks possess excellent optical properties, especially in ultraviolet (UV) and infrared (IR) wavelengths. This feature is of particular interest to industries requiring optical components with exceptional clarity.

5. High Purity: Derived from high-purity sources, fused silica bricks maintain an exceptional level of purity. This characteristic is critical in applications where even trace impurities can have a significant impact.

Applications of Fused Silica Bricks

Now that we have a better understanding of the properties that make fused silica bricks unique, let’s delve into the diverse range of applications where they shine:

1. Glass Manufacturing: The glass industry benefits greatly from the use of fused silica bricks. They are commonly employed in glass furnaces, especially in areas where rapid temperature fluctuations occur. Their ability to withstand such conditions helps maintain the integrity of the furnace, ensuring consistent glass production.

2. Ceramic Kilns: In the world of advanced ceramics, fused silica bricks find their place in critical areas of kilns. These bricks contribute to the stability and reliability of ceramic manufacturing processes, where precise temperature control is crucial.

3. Metal Casting: Foundry applications can be harsh environments for refractory materials due to the presence of corrosive slag and molten metal. Fused silica bricks, with their chemical resistance, provide an ideal solution in such settings, prolonging the life of crucibles and other furnace components.

4. Petrochemical Industry: High-temperature chemical processing in the petrochemical sector demands materials that can withstand extreme conditions. Fused silica bricks’ resistance to chemical corrosion and high thermal stability make them a valuable asset in this industry.

5. Other High-Temperature Applications: Beyond the mentioned industries, fused silica bricks are versatile and adaptable to various high-temperature settings. Any environment where materials are subjected to rapid temperature changes or where low thermal expansion is desired can benefit from the use of these bricks.

Kamroller Special Ceramics Co., Ltd.: A Leading Fused Silica Brick Supplier and Manufacturer

In the realm of fused silica brick suppliers and manufacturers, Kamroller Special Ceramics Co., Ltd. stands out as a prominent player. Established in 2006 through a collaboration between KAMROLLER® and China Tianhong Hi-Tech Industrial Ceramics Co., Ltd., this company has its roots in American technology and has built a state-of-the-art factory in China’s “Crystal Township.” Today, it proudly holds the title of the largest production base of fused silica products in Asia.

KAMROLLER, a name synonymous with high-tech ceramics since 1988, has extended its influence through factories and institutions in both the United States and China, serving customers worldwide with top-notch products and services.

Kamroller Special Ceramics Co., Ltd. offers a wide range of fused silica products, including fused silica bricks, fused silica tweels, and more. These products cater to a multitude of industries, such as glass manufacturing, solar energy, aerospace, building ceramics, metal heat treatment, natural energy resources, semiconductor manufacturing, steel production, petrochemicals, and beyond.

The company’s commitment to quality, innovation, and customer satisfaction has propelled it to the forefront of the fused silica industry. With a robust foundation in American technology and the vast resources of China’s industrial landscape, Kamroller Special Ceramics Co., Ltd. is well-equipped to meet the custom requirements of its clients and provide them with cutting-edge fused silica solutions.

Conclusion

In conclusion, fused silica bricks are indispensable in industries that require reliable, high-temperature refractory materials. Kamroller Special Ceramics Co., Ltd., as one of the leading fused silica brick suppliers and manufacturers, has established itself as a trusted provider of these specialized products. With their exceptional characteristics and diverse applications, fused silica bricks continue to play a vital role in enhancing the performance and longevity of critical industrial processes worldwide.

Post time: 12月-08-2023