Fused Silica Ceramic Brick

Introducing our Fused Silica Ceramic Brick, a high-performance and versatile refractory material for various industrial applications. Meticulously engineered using premium fused silica, this Brick offers exceptional thermal stability, excellent resistance to high temperatures.

The Fused Ceramic Brick is designed to withstand extreme heat, making it ideal for glass manufacturing, metal casting, kilns, furnaces, and other high-temperature processes. Its unique composition ensures minimal thermal expansion, preventing cracking or distortion.

With its dense and non-porous structure, the Fused Silica Ceramic Brick exhibits remarkable resistance to thermal shock, chemical corrosion, and abrasion. This ensures a prolonged service life and consistent performance, reducing downtime and maintenance costs. The Brick’s smooth and flat surface provides excellent contact and stability when used as a lining or support material.

This versatile Brick can be easily shaped, cut, or customized to meet specific requirements, allowing seamless integration into existing refractory systems. Its precise dimensions and uniformity enable precise heat distribution and effective insulation, optimizing energy efficiency and reducing heat loss. With its exceptional durability, thermal performance, and versatility, it will elevate your industrial processes, enhance productivity, and deliver consistent results.

Sizes Range: Fused Silica Ceramic Brick

Customized

Usage: Fused Silica Ceramic Brick

The Fused Silica Brick finds extensive usage in many industrial applications where high-temperature resistance and exceptional durability are paramount. It is a reliable choice for lining glass furnaces, constructing kilns and furnaces for metal casting, and providing thermal insulation in various high-temperature processes. With its ability to withstand extreme heat and resist thermal shock, chemical corrosion, and abrasion, the Ceramic Brick ensures long-lasting performance and minimal maintenance requirements. Its customizable nature allows easy integration into existing refractory systems. This also provides an effective heat distribution, insulation, and stability.

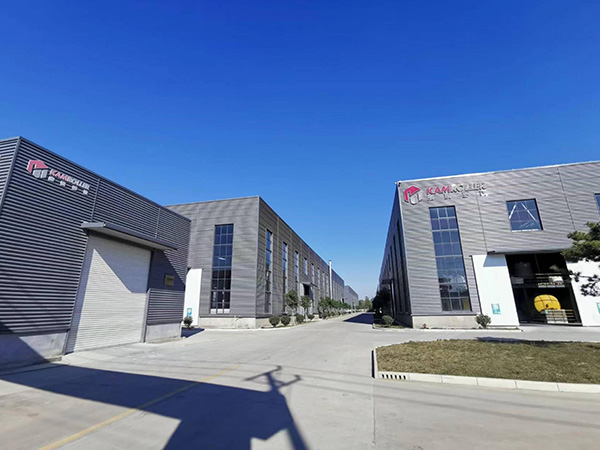

Our Factory Image:

Packing Detail:

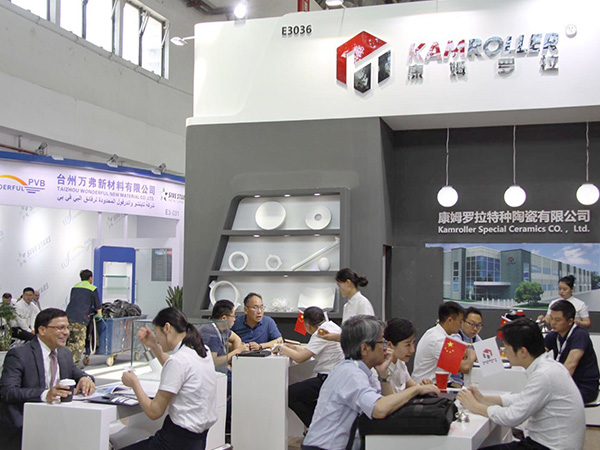

Kamroller At The Exhibition:

ISO Certificate:

- SiO₂ Purity (wt%)—≥99.7

- Bulk Density (g/cm³)—≥1.96

- Apparent Porosity (%)—≤10

- Compressive Strength (Rt) (Mpa)—≥60

- Bending Strength (FIT) (1100℃X0.5h) (Mpa)—≥28

- Thermal Expansion (X10ˉ6 /℃) ( RT-1000℃)—≤0.5

- Dimensional Tolerance (mm)—±0.05