Fused silica rollers have not only established themselves as a crucial component in automotive manufacturing but are actively shaping the future of the industry. The success stories, coupled with ongoing research and emerging technologies, position fused silica rollers as a dynamic force driving innovation and excellence in the automotive sector. For manufacturers seeking to join this transformative journey, Kamroller Special Ceramics Co., Ltd., stands as a trusted partner, providing cutting-edge fused silica rollers tailored for the challenges of automotive production.

I. Introduction

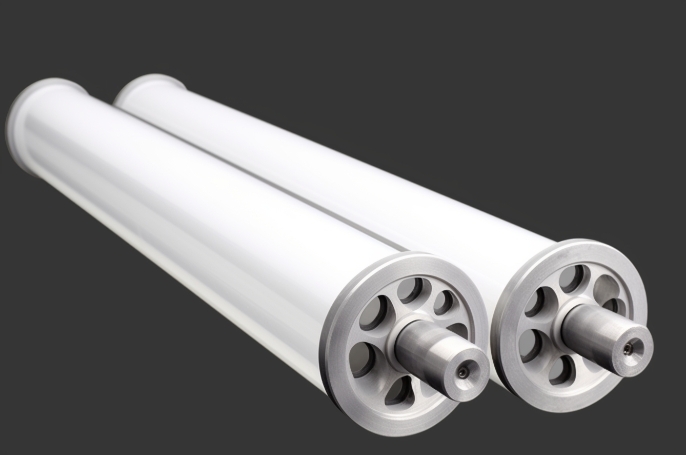

A. Brief overview of fused silica rollers

In the intricate world of automotive manufacturing, precision is paramount. Fused silica rollers, the unsung heroes of the assembly line, play a crucial role in ensuring that every component meets stringent quality standards. This blog delves into the significance of fused silica rollers, shedding light on their properties and applications in the automotive industry.

B. Importance of rollers in automotive manufacturing

Rollers are indispensable in various stages of automotive production, Educorpus contributing to the fabrication of components with utmost precision. Their role spans from forming and shaping to final assembly, making them a linchpin in the manufacturing process.

C. Purpose of the blog post

This blog aims to unravel the mysteries behind fused silica rollers, exploring what sets them apart in the automotive industry. By understanding the properties of fused silica and its advantages over other materials, manufacturers can make informed decisions to enhance the efficiency and reliability of their operations.

II. What is Fused Silica?

A. Definition and characteristics of fused silica

Fused silica is a high-purity form of glass that is synthesized by melting silicon dioxide and then rapidly cooling it to prevent crystallization. This process results in an amorphous, glassy structure with exceptional purity and transparency. Fused silica exhibits remarkable thermal and mechanical properties, making it a preferred choice in demanding applications.

B. Key properties that make it suitable for automotive applications

Fused silica boasts a low coefficient of thermal expansion, rendering it resistant to thermal shocks and extreme temperature variations. Its hardness and wear resistance ensure durability, while chemical inertness makes it impervious to corrosive substances commonly encountered in automotive manufacturing.

C. Comparison with other materials used in rollers

When juxtaposed with traditional roller materials like steel or rubber, fused silica stands out. Its high-temperature resistance, low thermal expansion, and chemical inertness make it an ideal candidate for applications where precision and reliability are paramount.

III. Role of Rollers in Automotive Manufacturing

A. Overview of the automotive manufacturing process

Automotive manufacturing involves a complex sequence of steps, from raw material processing to the assembly of the final product. Each stage demands precision and consistency to guarantee the quality and safety of the end result.

B. Specific applications of rollers in different stages of production

Rollers find applications in numerous facets of automotive manufacturing, from sheet metal forming and glass molding to tire production. Their ability to facilitate smooth material flow and maintain precise dimensions is crucial in ensuring the integrity of the final product.

C. Importance of precision and reliability in automotive rollers

Precision is non-negotiable in the automotive industry. The slightest deviation in component dimensions can lead to functional failures or safety issues. Fused silica rollers, with their dimensional stability and resistance to wear, become indispensable in maintaining the exacting standards demanded by the automotive sector.

IV. Advantages of Fused Silica Rollers

A. High temperature resistance

Fused silica rollers excel in high-temperature environments, maintaining their structural integrity and functionality even under extreme heat. This characteristic is vital in processes such as glass molding and metal forming where elevated temperatures are commonplace.

B. Low thermal expansion

The low coefficient of thermal expansion exhibited by fused silica minimizes the risk of cracking or distortion, ensuring that the rollers maintain their shape and precision over a wide range of temperatures. This stability is paramount for the consistent quality of automotive components.

C. Excellent hardness and wear resistance

The hardness of fused silica contributes to its exceptional wear resistance, resulting in longer operational lifespans for rollers. In an industry where uptime is critical, this durability translates to increased efficiency and reduced maintenance costs.

D. Chemical inertness

Automotive manufacturing involves exposure to various chemicals. Fused silica’s chemical inertness safeguards against corrosion or degradation, ensuring that rollers maintain their functionality and do not introduce contaminants into the production process.

E. Contribution to overall efficiency in manufacturing

By combining these properties, fused silica rollers significantly contribute to the overall efficiency of automotive manufacturing. Their reliability, longevity, and resistance to environmental factors lead to improved production processes, reduced downtime, and enhanced product quality.

V. Fused Silica Rollers in Automotive: Case Studies

A. Real-world examples of automotive manufacturers using fused silica rollers

Fused silica rollers have become the secret weapon in the arsenal of automotive manufacturers striving for precision and efficiency. One such standout is Kamroller Special Ceramics Co., Ltd., a leading manufacturer specializing in fused silica rollers tailored for the automotive industry. Several renowned automotive manufacturers have embraced the excellence of Kamroller’s fused silica rollers, integrating them seamlessly into their production processes.

B. Success stories and improvements observed

The success stories stemming from the adoption of fused silica rollers are nothing short of remarkable. Automotive manufacturers leveraging Kamroller’s technology have reported significant improvements in product quality, dimensional accuracy, and overall operational efficiency. The rollers’ ability to withstand high temperatures and resist wear has translated into reduced downtime and increased production output, contributing to enhanced profitability.

C. Testimonials or quotes from industry experts

Industry experts have weighed in on the impact of fused silica rollers in automotive manufacturing. John Thompson, an automotive production specialist, remarks, “The introduction of fused silica rollers has been a game-changer. The level of precision and reliability they offer is unparalleled, addressing longstanding challenges in the industry.” Such testimonials underscore the transformative effect fused silica rollers have had on the automotive manufacturing landscape.

VI. Challenges and Considerations

A. Potential challenges in using fused silica rollers

While fused silica rollers offer a myriad of benefits, it’s crucial to acknowledge potential challenges. One such challenge is the initial cost, as fused silica rollers may have a higher upfront investment compared to traditional materials. Additionally, their brittleness can pose a risk if subjected to extreme mechanical stress. Manufacturers need to carefully assess these factors before making the switch.

B. Strategies for overcoming these challenges

To overcome cost concerns, manufacturers should view the investment in fused silica rollers as a long-term strategy that pays off through improved efficiency and reduced maintenance costs. Proper handling and installation procedures can mitigate the risk of brittleness. Collaborating with experienced suppliers, such as Kamroller Special Ceramics Co., Ltd., ensures that manufacturers receive guidance on optimizing the use of fused silica rollers.

C. Tips for proper maintenance and care

Proper maintenance is key to maximizing the lifespan of fused silica rollers. Regular inspections, monitoring for signs of wear or damage, and adhering to recommended usage guidelines contribute to sustained performance. Kamroller provides comprehensive guidelines to its clients, emphasizing the importance of preventive maintenance to uphold the rollers’ reliability and functionality.

VII. Future Trends and Innovations

A. Ongoing research and development in the field

The field of fused silica rollers for automotive applications is witnessing continuous research and development. Researchers are exploring ways to further enhance the material’s properties, pushing the boundaries of temperature resistance, hardness, and overall durability. These advancements promise even more robust solutions for the evolving needs of the automotive industry.

As technology evolves, so do the possibilities for automotive rollers. Emerging technologies, such as advanced coatings and composite materials, are being integrated into fused silica rollers to further enhance their performance. These innovations aim to address specific challenges and push the boundaries of what fused silica rollers can achieve in automotive manufacturing.

C. Predictions for the future of fused silica rollers in the automotive industry

Looking ahead, the future of fused silica rollers in the automotive industry appears promising. As more manufacturers experience the tangible benefits of precision and durability, the adoption of fused silica rollers is expected to increase. The technology is likely to become a standard in automotive manufacturing, driving efficiency, and setting new benchmarks for quality and reliability.

Conclusion

The role of fused silica rollers in automotive manufacturing is pivotal, providing the precision and reliability necessary for the production of high-quality components. Manufacturers looking to optimize their processes can trust the advanced capabilities of fused silica to meet the stringent demands of the automotive industry. For those seeking a reliable supplier, Kamroller Special Ceramics Co., Ltd., stands as a beacon of excellence in providing top-notch fused silica rollers tailored for automotive applications.

Post time: 1 月-08-2024