What does “fused spherical silica” mean?

Due to its outstanding qualities and adaptability, fused spherical silica, also known as fused silica or fused quartz, is a fascinating material used in various sectors. This particular variety of glass is made mostly of silicon dioxide (SiO2). The same substance makes up the regular glass but has undergone a special manufacturing process that gives it special properties. The word “fused” in fused silica refers to the manufacturing process. High-purity quartz or silica sand crystals are melted to a liquid state at temperatures between 2000 and 3000 degrees Celsius to produce this substance.

The required form is then meticulously crafted from molten silica, frequently using beads or other complex forms. Its complete lack of crystalline structure, which results in an amorphous, glassy material, is the secret to its outstanding quality. Spherical silica’s spherical component refers to the generated particles’ final form. Due to their remarkable uniformity in size and shape, these microspheres are extremely useful in a variety of applications. These particles are perfect for usage as fillers, coatings, and in some types of composite materials because of their spherical shape, which promotes smooth flow and packing.

The Magic of Fused Spherical Silica: Unleashing Precision’s Power

Certain compounds stand out in the large field of materials science for their composition and the creative methods used to create them. Fused spherical silica, a substance that embodies accuracy, adaptability, and quality in its own structure, is one such miracle. Let’s go on an adventure to discover the mysteries of this amazing chemical and the many ways it has transformed industries throughout the world.

- The Beginning of Accuracy:

High-purity silica sand or quartz crystals are the basis of the painstaking manufacturing process that yields spherical silica, also known as fused quartz. Through extreme heat, these basic materials are transformed in a magnificent way. Imagine exposing them to heat as high as 3000 degrees Celsius, which would cause them to liquefy like a river of molten glass. The distinctive “fused spherical” name is derived from the subsequent shaping of this molten silica into spherical beads.

- Crystal-clear characteristics:

Fused spherical silica is unusual in that it lacks a crystalline structure. In contrast to typical glass, which frequently displays a recurring molecular pattern, this substance is an amorphous marvel. Due to its distinctive structural design, it has a number of outstanding qualities that make it valuable in a variety of sectors.

- Thermal Resilience Unmatched by Comparison:

The exceptional resilience of spherical silica to high and low temperatures is one of its most amazing properties. In extreme heat, other materials may fail, but this glass holds strong, demonstrating its actual strength. It is important in situations where thermal stability is a must since it can withstand extreme heat without cracking or giving way to expansion and contraction.

Understanding the amazing Fused Spherical Silica’s Properties and Applications:

Few substances in the world of sophisticated materials display the extraordinary mix of features and uses that spherical silica does. Due to its extraordinary qualities and diverse possibilities, this unusual substance, also known as fused quartz, has caught the attention of scientists, engineers, and inventors from a variety of sectors.

- Thermal Stability:

This silica stands out for its outstanding resilience to high and low temperatures. Fused silica is essential in applications involving quick temperature fluctuations or exposure to extreme heat because it does not break or distort under high heat as many other materials do.

- Optical Transparency:

Outstanding optical transparency throughout a broad range, including ultraviolet, visible, and infrared wavelengths, is a feature of fused spherical silica. This makes it a top option for optical applications where preserving clarity and accuracy is crucial, such as premium lenses and windows for different optical instruments.

- Low Thermal Expansion:

It is a great material for applications that require dimensional stability in the face of temperature fluctuations due to its low thermal expansion coefficient. Industries like electronics and aircraft can benefit from this characteristic.

- Chemical Inertness:

Because of its amorphous structure and chemical inertness, spherical silica is resistant to corrosion by the majority of chemicals. Because of this, it is useful in settings where exposure to severe chemicals or corrosive materials is typical.

Applications in Different Sectors:

Fused spherical silica is adaptable and useful in a wide number of sectors, as evidenced by its flexibility.

- Electronics:

Due to its poor electrical conductivity, spherical silica excels as an insulating material in the electronics industry. Circuit breakers, high-voltage insulators, and other parts that require electrical insulation utilize it.

- Optics:

It is a crucial component of optics due to its optical transparency and accuracy. It is used to make lenses, windows, prisms, and mirrors for different optical devices, such as microscopes, telescopes, and lasers.

- Aerospace and Automotive:

The material is extremely useful in aerospace and automotive applications because of its thermal stability and resistance to thermal shock. It is utilized in parts that go through drastic temperature fluctuations, such as sensors and engine parts.

- Medical Technology:

It is employed in drug delivery devices in biotechnology and pharmaceuticals. Because of its inertness, pharmacological substances are released safely and under control, boosting the efficacy of therapies.

Conclusion:

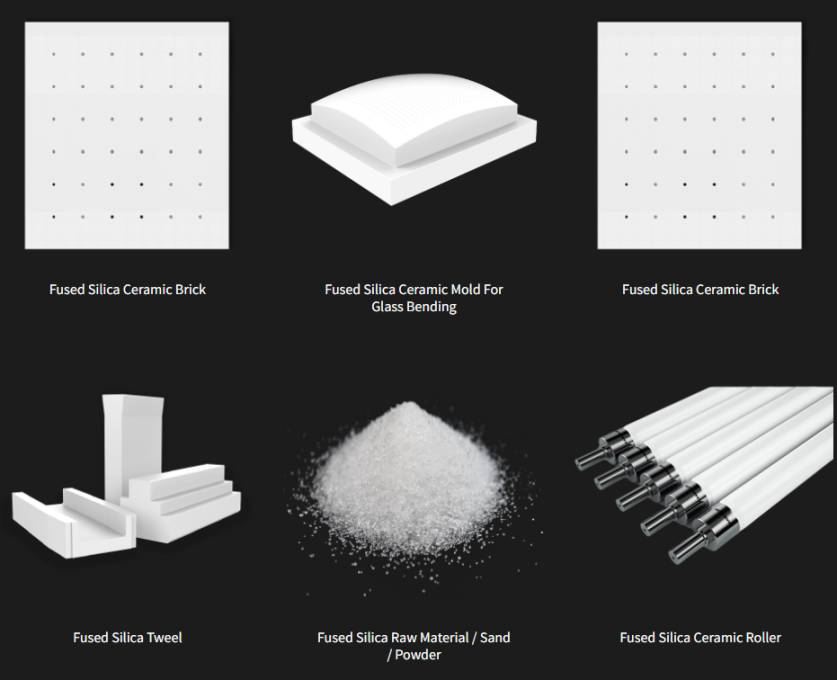

To sum up, fused spherical silica is a monument to the inventiveness of material science. It may transform a wide range of sectors because of its distinctive combination of qualities obtained via a rigorous production procedure. The business has always upheld the idea of “reducing energy loss for the earth” by giving society high-performance ceramic goods and lowering demand on the planet. KAMROLLER is committed to becoming a developer and operator of global ceramics with global influence and competitiveness and works to maximize stakeholders’ value. Kamroller is driven by innovation, pursues excellence, and cherishes the vision of “becoming a leader in the ceramic industry.”

Post time: 8 月-23-2023