The automotive industry is no stranger to innovation and adaptation, constantly seeking advanced materials and technologies to improve vehicle performance and durability. Kamroller Special Ceramics Co., Ltd., a leading high-tech ceramics manufacturer, plays a pivotal role in addressing the industry’s evolving needs and challenges.

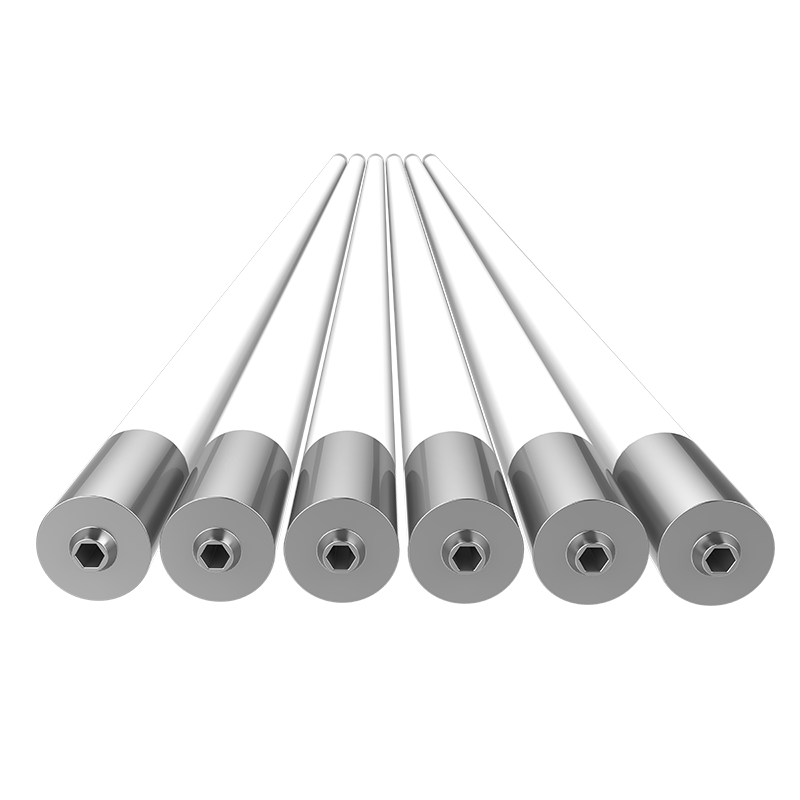

As automotive manufacturers and auto parts producers increasingly turn to ceramic materials for their exceptional mechanical strength, thermodynamics, and electrical properties, Kamroller steps in to provide reliable, durable, and cost-effective solutions. In this article, we’ll explore the needs and challenges faced by the automotive industry and how Kamroller is providing cutting-edge solutions, with a focus on their Fused Silica Roller for Automotive Parts Annealing Furnace.

Challenges in the Automotive Industry: Best High-Tech Ceramics Manufacturer

The automotive industry operates in an environment of intense competition and rapid technological advancements. As manufacturers strive to produce high-performance vehicles with enhanced mechanical properties, they encounter several challenges:

1. Heat Treatment and Mechanical Enhancement: One of the crucial processes in automotive manufacturing is heat treatment, which improves the mechanical properties of vehicle components. Achieving precise and controlled heat distribution is a challenge, as traditional materials often fail to withstand the extreme temperatures required for annealing.

2. Surface Contamination: Surface contamination during heat treatment can lead to defects in automotive parts. Reducing material adhesion and ensuring a smooth, non-porous surface is essential for maintaining the quality and integrity of the components.

3. Chemical Compatibility: The automotive industry uses a wide range of materials and processes. Ensuring that the components used in these processes are chemically compatible with the environment in which they operate is crucial to avoid corrosion and undesirable effects on automotive parts.

4. Downtime and Maintenance: Frequent equipment maintenance and replacements can lead to downtime in manufacturing facilities, impacting production efficiency. Manufacturers need long-lasting, reliable components that require minimal maintenance.

Kamroller Special Ceramics Co., Ltd.: Solving Automotive Industry Challenges

Kamroller, a high-tech ceramics manufacturer, addresses these challenges with innovative solutions. Their Fused Silica Roller for Automotive Parts Annealing Furnace is a prime example of how they cater to the specific needs of the automotive industry.

1. Exceptional Heat Resistance: The Fused Silica Roller is engineered to withstand the intense temperatures of annealing processes. Its superior heat resistance ensures consistent and controlled heat distribution, leading to improved mechanical properties in automotive components.

2. Minimized Surface Contamination: The smooth and non-porous surface of the Fused Silica Roller minimizes material adhesion, preventing surface contamination. This is crucial for ensuring the quality and integrity of the heat-treated automotive parts.

3. Chemical Compatibility: Kamroller’s Fused Silica Roller offers exceptional chemical resistance, making it compatible with a wide variety of automotive materials and processes. It resists corrosion and chemical reactions, ensuring that it doesn’t negatively impact the automotive parts during heat treatment.

4. Long Service Life: The durability of the Fused Silica Roller guarantees a long service life. This reduces the need for frequent replacements and maintenance, ultimately minimizing downtime and optimizing production efficiency in automotive manufacturing facilities. Its high wear resistance ensures consistent performance and excellent results, while also offering a cost-effective solution for manufacturers.

Supply Chain and Manufacturing Insights: Professional High-Tech Ceramics Manufacturer

1. Precision Manufacturing: Best High-Tech Ceramics Manufacturer

High-Tech Ceramics Manufacturer like Kamroller Special Ceramics is committed to delivering top-quality ceramic components to meet the demands of the automotive industry. They leverage precision manufacturing techniques to ensure that their products consistently meet stringent industry standards. Their expertise in ceramics manufacturing allows them to develop components that are not only durable but also highly efficient.

2. Quality Control: Professional High-Tech Ceramics Manufacturer

Quality control is a cornerstone of Kamroller’s operations. They employ rigorous quality control processes at every step of manufacturing, from raw material inspection to final product testing. This commitment to quality ensures that their ceramic components are reliable, resilient, and capable of withstanding the harsh conditions of the automotive sector.

3. Reliability of Supply Chain: Best High-Tech Ceramics Manufacturer

Kamroller understands the importance of a reliable supply chain in today’s fast-paced automotive industry. They have established a robust supply chain network that guarantees consistent access to high-quality ceramic materials and components. This commitment to supply chain reliability makes them an ideal partner for businesses seeking dependable and consistent sources of high-tech ceramics.

Frequently Asked Questions (FAQs): Best High-Tech Ceramics Manufacturer

1. What sets high-tech ceramics apart from traditional materials in the automotive industry?

High-tech ceramics, such as those offered by Kamroller, possess remarkable mechanical strength and exceptional thermodynamic and electrical properties. These qualities make ceramics a superior choice in applications where traditional metals may fail, offering enhanced durability and performance.

2. How can Kamroller assist automotive manufacturers and auto parts suppliers?

Kamroller collaborates closely with automotive manufacturers and auto parts suppliers to develop reliable, durable, and cost-effective ceramic components. Their expertise in ceramics manufacturing allows them to tailor solutions that meet the specific needs of their partners, contributing to improved product performance and longevity.

3. What quality control measures does Kamroller employ?

Kamroller follows stringent quality control processes throughout the manufacturing cycle. This includes rigorous inspections of raw materials, precision manufacturing techniques, and comprehensive product testing. These measures ensure that the ceramic components delivered by Kamroller meet the highest industry standards.

4. Is Kamroller’s supply chain reliable?

Yes, Kamroller takes pride in its dependable supply chain network. By maintaining close relationships with suppliers and carefully monitoring the procurement of raw materials, they ensure a consistent and reliable source of high-quality ceramics. This reliability is crucial for businesses seeking consistent access to these high-tech materials.

5. How can my business collaborate with Kamroller?

To explore collaboration opportunities with Kamroller, simply reach out to their dedicated team of experts (Email: marketing@kamroller.com; Tel: +86-0516-88958936 / +86-18811957088). They are ready to discuss your specific requirements and tailor a solution that best suits your needs in the realm of high-tech ceramics for the automotive industry.

Conclusion

Professional High-Tech Ceramics Manufacturer like Kamroller Special Ceramics Co., Ltd. is at the forefront of addressing the automotive industry’s needs and challenges by providing high-performance ceramic components. Their Fused Silica Roller for Automotive Parts Annealing Furnace is a testament to their commitment to innovation and their dedication to helping automotive manufacturers produce high-quality, durable vehicles. As the automotive industry continues to evolve, Kamroller will undoubtedly remain a key partner in delivering cutting-edge ceramic solutions for the industry’s ever-changing demands.

Post time: 10 月-25-2023