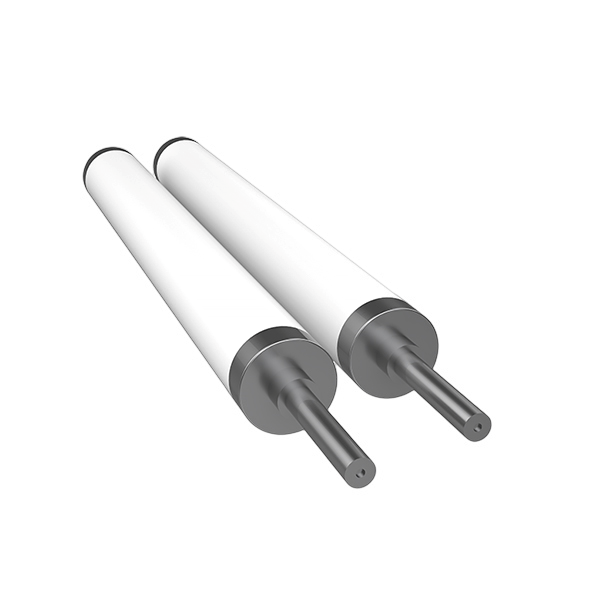

Kamroller Glass Annealing Roller

Introducing the Kamroller Glass Annealing Roller, a premium solution designed to meet the exacting demands of glass annealing processes. With precision engineering and high-quality materials, this roller offers glass manufacturers exceptional performance, reliability, and durability.

The Kamroller Glass Roller is specifically crafted for use in glass annealing kilns, where it plays a crucial role in supporting and transporting glass during the annealing process. It’s robust construction and specialized design ensure stable and precise movement of glass sheets or objects, preventing distortion or damage during the cooling phase.

With its superior heat resistance, the Roller can withstand the high temperatures encountered in glass annealing. This ensures a consistent and controlled cooling rates for optimal stress relief and enhanced glass strength. Its smooth and non-porous surface minimizes the glass sticking or marking risk. This facilitate a smooth and uniform glass movement throughout the annealing cycle.

The Kamroller Glass Roller is meticulously engineered to provide excellent dimensional stability, ensuring accurate positioning of glass objects for uniform heat distribution. This reduces internal stresses, improves flatness, and enhances overall glass quality. Its high wear resistance and durability ensure a long service life, reducing maintenance and replacement costs.

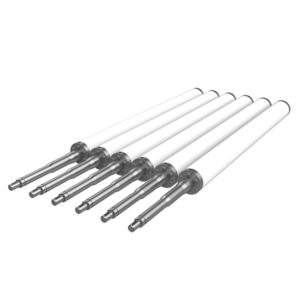

Usage: Kamroller Glass Annealing Roller

The Kamroller Glass Roller is specifically designed for use in glass manufacturing processes, particularly in glass annealing kilns. This roller is critical for supporting and transporting glass sheets or objects during the annealing process. It moreover ensures a precise and controlled cooling for optimal stress relief and improved glass strength.

By utilizing the Kamroller Roller, glass manufacturers can achieve consistent and uniform cooling rates. It minimize the risk of distortion or damage to the glass. This roller’s exceptional heat resistance allows it to withstand the high temperatures encountered in glass annealing, guaranteeing reliable performance and longevity in demanding manufacturing environments.

|

Fuse Silica Roller Specifications |

|

| SiO2 (wt%) Purity | ≥99.6 |

| Color | White |

| Max Using Temperature | 1250℃ |

| Density (g/cm³) | ≥1.8-2.1 |

| Apparent Porosity (%) | 5-20 |

| Compressive Strength (Rt) (Mpa) | ≥60 |

| Bending Strength (FIT) (1100℃X0.5h) (Mpa) | 20-70 |

| Thermal Expansion (X10-6/℃) (RT-1000℃) | 0.54×10-6 |

| Thermal Conductivity Coefficient (w/m·s·k) | ≤0.5 |

| Thermal Shock Resistance | 1200℃-20℃

Thermal Shock > 20 Times |

| Moh’s Hardness | 7 |