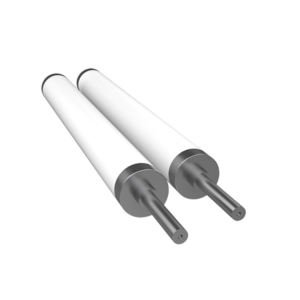

Silicon Steel Bottom Annealing Roller

Introducing our Silicon Steel Bottom Annealing Roller, a specialized and high-performance solution designed specifically for the annealing process. Crafted with precision and utilizing advanced silicon steel materials, this roller offers exceptional heat resistance, and reliability in demanding industrial applications.

The Silicon Bottom Roller is specifically engineered for bottom annealing furnaces where silicon steel sheets undergo critical heat treatment. With its superior heat resistance, the roller can withstand the extreme temperatures and thermal cycling of the annealing process. This also ensures consistent and controlled heat distribution for precise results.

The precision machining and surface finish of the Silicon Bottom Roller minimize surface imperfections. It also ensures smooth and uniform contact with the silicon steel sheets. This guarantees even heat transfer, minimizing the risk of surface irregularities and distortions in the annealed material and ultimately. It also enhance the quality and performance of the silicon steel sheets.

Furthermore, the Silicon Annealing Roller exhibits exceptional dimensional stability, maintaining precise positioning of the silicon steel sheets throughout the annealing process. This ensures uniform heat treatment. It also prevents warping or deformation of the sheets and resulting in consistent desired grain structures.

Usage: Silicon Steel Bottom Annealing Roller

The Silicon Steel Annealing is designed for precise and efficient annealing of silicon steel sheets, making it an essential component in manufacturing. This specialized roller is used in bottom annealing furnaces, where it can withstand the high temperatures and thermal cycling required for optimal heat treatment. The roller ensured uniform and controlled heat distribution with superior heat resistance. It results in consistent magnetic properties and desired grain structures in the silicon steel sheets. Its precision machining and dimensional stability provide smooth and uniform contact with the sheets. This also minimize the surface imperfections and maintaining their integrity.

|

Fuse Silica Roller Specifications |

|

| SiO2 (wt%) Purity | ≥99.6 |

| Color | White |

| Max Using Temperature | 1250℃ |

| Density (g/cm³) | ≥1.8-2.1 |

| Apparent Porosity (%) | 5-20 |

| Compressive Strength (Rt) (Mpa) | ≥60 |

| Bending Strength (FIT) (1100℃X0.5h) (Mpa) | 20-70 |

| Thermal Expansion (X10-6/℃) (RT-1000℃) | 0.54×10-6 |

| Thermal Conductivity Coefficient (w/m·s·k) | ≤0.5 |

| Thermal Shock Resistance | 1200℃-20℃

Thermal Shock > 20 Times |

| Moh’s Hardness | 7 |