What is a silicon steel bottom annealing roller?

A specialized item used in steel production, namely in silicon steel sheets or strips, is a silicon steel bottom annealing roller. A kind of alloy with low core loss and high magnetic permeability, silicon steel—also referred to as electrical steel or transformer steel—is ideal for use in transformers, electric motors, and generators.

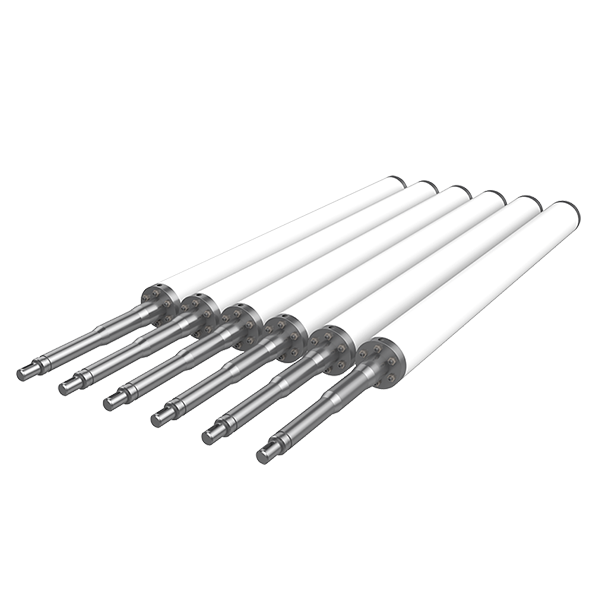

An important process in producing silicon steel is annealing, which entails heating the material to a specified temperature and then gently cooling it. Internal tensions are reduced, magnetic properties are enhanced, and this procedure improves the steel’s grain structure. The bottom annealing roller is an essential component of the annealing furnace utilized in this procedure. To endure the high temperatures needed in the annealing process, it is often composed of a heat-resistant material, such as a heat-resistant alloy or ceramic. The silicon steel sheets or strips are supported as they move through the furnace by the roller, which is placed at the bottom.

The main purpose of silicon steel bottom annealing roller:

One kind of roller frequently used in steel production is a silicon steel bottom annealing roller. It consists of a silicon steel outer shell filled with a substance like graphite or alumina. The roller is heated to a level that enables the steel strip to be annealed. The silicon steel material must be moved through the annealing furnace in a regulated and smooth manner, and this is the major goal of the bottom annealing roller. During the heating and cooling processes, it aids in preventing deformation or damage to the steel. The design of the roller and its surface characteristics were carefully thought out to reduce the possibility of silicon steel being scratched, marked, or contaminated.

Temperature range of silicon steel bottom annealing roller:

For severe annealing procedures like those used in steel production, silicon steel annealing rollers are appropriate. The temperature range is 600-950 °C, which is used for annealing on high-temperature silicon steel sheets. To achieve a smooth and predictable delivery, Kamroller exclusive, patented shaft end technology is employed with the roller table, customized to satisfy the process requirements. Additionally, manufacturing dimensional accuracy’s surface roughness is tightly regulated.

Why is a silicon steel bottom annealing roller important?

They are essential elements utilized in the heat treatment process of silicon steel sheets and are also referred to as silicon steel radiant tubes. They become essential parts of the heat treatment of silicon steel sheets because of these benefits, allowing the creation of high-quality materials for various electrical applications. These rollers’ Numerous advantages improve the process’s effectiveness, calibre, and overall performance. Let’s examine what is a silicon steel bottom annealing roller? And its benefits in more depth.

Resistance to High Temperatures:

Silicon steel bottom annealing rollers are made to withstand high temperatures frequently encountered during annealing. The durability and dependability of the heat treatment procedure are ensured by their capacity to tolerate temperatures of up to 1300°C (2372°F) without warping or deforming.

Excellent Heat transmit:

Thanks to the rollers’ distinctive shape, the silicon steel sheets and the heating medium can transmit Heat very well. The steel sheets’ magnetic characteristics and grain orientation are enhanced by the constant annealing caused by the even heating of the rollers’ surface.

Energy Efficiency:

During annealing, silicon steel bottom annealing rollers help conserve energy. The energy needed to reach and maintain the necessary annealing temperature is decreased by their outstanding heat transmission capabilities, which also minimize heat loss. Energy efficiency reduces costs and improves the environment.

Durability and lifespan:

Using premium silicon steel in the manufacturing guarantees these rollers’ durability and lifespan. Due to their resistance to oxidation, corrosion, and wear, they can endure severe heat treatment settings for longer periods. Reduced maintenance needs and higher output are the results of its resilience.

Precision and Consistency:

Due to the rollers’ exact manufacturing process and dimensional stability, the silicon steel sheets’ whole surface will be consistently annealed. This is accomplished by distributing Heat evenly throughout the rollers’ construction. Uniformity is essential to obtain the required grain structure and magnetic characteristics, which eventually improve the finished product’s overall quality.

Surface imperfections on Steel Sheets are Reduced:

Silicon steel bottom annealing rollers help to reduce surface imperfections on the steel sheets. Their flawless finish and superior construction shield them from blemishes that adversely impact the sheet’s magnetic characteristics or future processing stages.

Increased Productivity:

These rollers’ excellent heat transmission and reliable annealing enable increased process effectiveness and productivity. Shorter and more consistent heat treatment cycles make increased production capacity and greater throughput possible.

Improved Magnetic characteristics:

The bottom annealing rollers of silicon steel are essential for enhancing the steel sheets’ magnetic characteristics. The rollers assist in aligning the silicon steel’s crystal grains during precision heat treatment, which improves magnetic permeability, reduces core losses, and increases electrical efficiency in devices like transformers and electric motors.

Compatibility with Different Annealing Processes:

Silicon steel bottom annealing rollers are adaptable to several annealing procedures, including batch annealing, continuous galvanizing lines, and continuous annealing. These techniques include continuous annealing and continuous annealing. This adaptability guarantees their usefulness for various production applications, giving steel manufacturers options.

Industry Compatibility:

These rollers are compatible with and by accepted annealing procedures since they follow industry norms and regulations. The performance and quality of the rollers may be relied upon by manufacturers to satisfy the demanding criteria and requirements of silicon steel manufacturing.

Conclusion:

What is a silicon steel bottom annealing roller? It is precisely described in the above information. When making electrical components, silicon steel bottom annealing rollers heat-treat steel. The rollers are made to deliver even and effective heat transmission and even and reliable cooling. They are made to reduce surface tension and eliminate the possibility of oxidation. The premium silicon steel bottom annealing roller was created by KAMROLLER to satisfy client demands. The purchase you made serves a purpose. You can count on us all the time, not just once. The fulfilment of whatever desires you may have been our primary goal. Visit our website today to take advantage of all of its fantastic features. Make a purchase soon!

Post time: 5 月-16-2023