China has emerged as a prominent player in the world of ceramics, particularly in the field of China Customized OEM Fused Silica Ceramic. These specialized materials have gained significance across various industries due to their exceptional properties, making them ideal for a wide range of applications.

I. Introduction: OEM Solutions in China — China Customized OEM Fused Silica Ceramic

A. Understanding OEM in Fused Silica Ceramics

In the context of fused silica ceramics, OEM, which stands for Original Equipment Manufacturer, refers to the practice of outsourcing the production of specialized ceramic components to a manufacturer in China like Kamroller Special Ceramics Co., Ltd. These components are often integral parts of larger systems or equipment used across various industries. By partnering with an OEM supplier, businesses can obtain tailor-made fused silica ceramic components designed to meet their specific requirements.

B. Benefits of Choosing OEM Solutions in China

Opting for OEM solutions in China offers several advantages. First and foremost is cost-effectiveness. China’s well-established manufacturing infrastructure allows for competitive pricing without compromising on quality. Businesses can save on production costs while receiving high-quality fused silica ceramic components.

Additionally, working with OEM suppliers like Kamroller Special Ceramics Co., Ltd. provides access to specialized expertise. These manufacturers have extensive knowledge of fused silica ceramics, ensuring that the final product meets the highest industry standards. Moreover, OEM solutions often include comprehensive support, from design consultation to production and delivery, making the entire process seamless for businesses.

II. What is Fused Silica Ceramic? — China Customized OEM Fused Silica Ceramic

A. Defining Fused Silica Ceramic

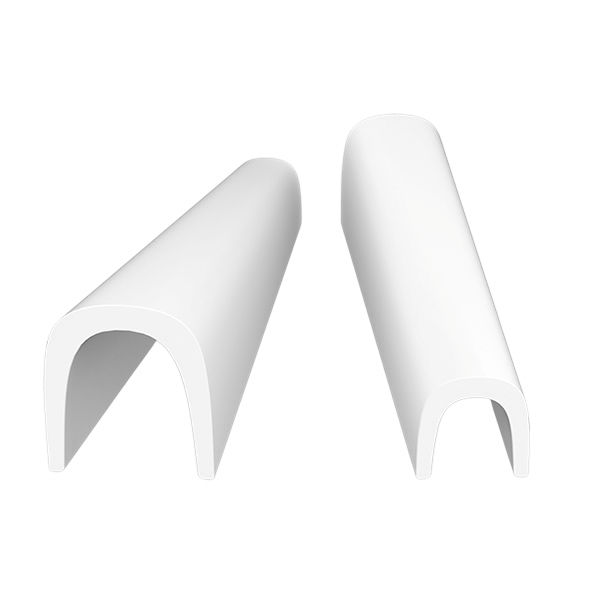

Fused silica ceramic, often referred to as fused quartz ceramic, is a specialized type of ceramic material known for its high purity and exceptional thermal and mechanical properties. It is created through a complex process that involves melting high-purity silica (SiO2) and then rapidly cooling it to form an amorphous, glassy structure. This unique manufacturing process results in a material with low thermal expansion, excellent thermal stability, and high resistance to heat and corrosion.

B. Advantages in Various Industries

Fused silica ceramics find applications in a diverse array of industries, owing to their remarkable characteristics. For instance, in the semiconductor industry, they are used as crucibles, wafer carriers, and other critical components due to their high purity and low contamination potential.

The optical industry relies on fused silica ceramics for their exceptional transparency and minimal optical distortion, making them ideal for precision lenses and windows. In the aerospace sector, their resistance to extreme temperatures and excellent thermal shock resistance make them crucial for aerospace components. These examples illustrate how the unique properties of fused silica ceramics enable their use in demanding applications.

III. The Importance of Customization — China Customized OEM Fused Silica Ceramic

A. Customized Solutions in the Fused Silica Ceramic Industry

In the world of ceramics, one size certainly does not fit all. Different industries have varying requirements, and even within the same industry, specific applications may demand distinct characteristics from the materials used. This is where customization becomes crucial.

China Customized OEM Fused Silica Ceramic solutions offer the flexibility to tailor the material’s properties to meet the exact needs of a given application. Whether it’s adjusting thermal conductivity, mechanical strength, or chemical resistance, customization ensures that the final product performs optimally.

B. Meeting Specific Application Needs

Consider the semiconductor industry, where stringent purity and thermal stability requirements exist. Customization allows manufacturers to produce fused silica ceramics with precisely the right level of impurity control and thermal properties required for their semiconductor equipment.

In contrast, the optical industry may prioritize the optical clarity and homogeneity of the material, necessitating customization to achieve the desired transparency and minimal birefringence. Thus, customization ensures that fused silica ceramics can excel in diverse applications while meeting specific criteria.

IV. China’s Expertise in Fused Silica Ceramic — China Customized OEM Fused Silica Ceramic

A. Overview of China’s Position

China has risen to prominence as a global leader in providing customized OEM fused silica ceramic solutions. The country’s ceramics industry, supported by cutting-edge technology and a skilled workforce, has rapidly evolved to meet the demands of various industries worldwide.

Kamroller Special Ceramics Co., Ltd. is a prime example of a Chinese manufacturer at the forefront of this industry. They have gained recognition for their expertise in producing high-quality fused silica ceramics tailored to individual customer requirements.

B. Reasons Behind China’s Expertise

Several factors have contributed to China’s success in the fused silica ceramic industry.

1. Resource Availability: China has abundant reserves of high-purity silica, a key raw material for fused silica ceramics, ensuring a steady supply and cost-effectiveness.

2. Investment in Technology: Chinese companies have heavily invested in research and development, allowing them to innovate and develop advanced manufacturing processes for fused silica ceramics.

3. Skilled Workforce: China boasts a large pool of skilled engineers and technicians who have the expertise to produce customized ceramics with precision.

4. Cost-Competitive Production: China’s efficient production processes and economies of scale have made it possible to offer competitive pricing without compromising quality.

5. Global Supply Chain: Chinese manufacturers have established a global supply chain network, ensuring timely delivery of customized OEM solutions to customers worldwide.

V. Case Studies — China Customized OEM Fused Silica Ceramic

To illustrate the benefits of choosing China’s customized OEM fused silica ceramic solutions, here are two case studies:

1. Semiconductor Equipment Manufacturer: A semiconductor equipment manufacturer collaborated with Kamroller Special Ceramics Co., Ltd. to develop customized fused silica ceramic wafer carriers. The tailored design and exceptional thermal stability of these carriers led to reduced contamination and increased yield in semiconductor production, resulting in significant cost savings and improved product quality.

2. Optical Telescope Manufacturer: A leading optical telescope manufacturer partnered with Kamroller to produce customized fused silica lenses for high-performance telescopes. These lenses delivered unparalleled optical clarity, enhancing the quality of astronomical observations and solidifying the manufacturer’s position as an industry leader.

VI. Future Trends and Innovations — China Customized OEM Fused Silica Ceramic

A. Emerging Trends and Innovations

The fused silica ceramic industry is continually evolving, driven by emerging trends and innovations. One notable trend is the development of advanced coatings and surface treatments that enhance the properties of fused silica ceramics, such as increased resistance to wear and improved optical performance.

B. Impact on OEM Solutions

These emerging trends in fused silica ceramics are likely to have a significant impact on OEM solutions. Customized components will increasingly incorporate these innovations to meet the ever-growing demands of various industries. As the industry continues to evolve, businesses can expect even more tailored solutions and improved performance from their OEM suppliers in China.

Conclusion

In conclusion, the world of fused silica ceramics is evolving, driven by the need for specialized materials with exceptional properties. China Customized OEM Fused Silica Ceramic solutions have become indispensable in various industries, and China, with its vast resources, technological prowess, and skilled workforce, has emerged as a global leader in this field. Kamroller Special Ceramics Co., Ltd. is a shining example of how Chinese manufacturers are meeting the demands of industries worldwide, providing customized fused silica ceramic solutions that power innovation across the globe.

Post time: 11 月-14-2023