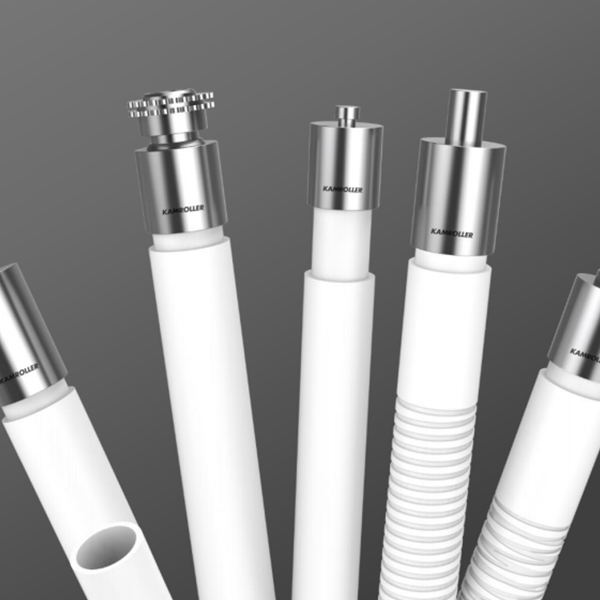

The world of industrial manufacturing is a fast-paced and ever-changing environment. This is where Fused Silica Ceramic Roller Manufacturers like Kamroller Special Ceramics Co., Ltd. step in to play a crucial role. These specialized manufacturers produce high-quality fused silica ceramic rollers that find applications in a wide range of industries, ultimately enhancing productivity and ensuring the highest standards of quality. In this blog, we will explore how Fused Silica Ceramic Roller Manufacturers improve industrial efficiency, the top qualities to look for in such manufacturers, and how they cater to diverse industries.

How Fused Silica Ceramic Roller Manufacturers Improve Industrial Efficiency?

Fused silica ceramic rollers are engineered to withstand extreme temperatures, exhibit exceptional hardness, and offer excellent thermal stability. These qualities make them indispensable components in various industrial processes, such as glass production, steel manufacturing, and semiconductor fabrication.

One key way Fused Silica Ceramic Roller Manufacturers like Kamroller Special Ceramics Co., Ltd. improve industrial efficiency is by providing rollers that are highly resistant to wear and corrosion. This durability ensures a longer service life, reducing downtime for maintenance and replacement. As a result, industries can operate continuously, leading to improved productivity and cost savings.

Moreover, fused silica ceramic rollers have excellent thermal properties, including low thermal expansion and high thermal conductivity. This makes them ideal for use in high-temperature environments, such as glass annealing and tempering furnaces. Their ability to maintain dimensional stability at elevated temperatures ensures consistent product quality and reduces the risk of defects.

Top Qualities to Look for in Fused Silica Ceramic Roller Manufacturers

When choosing Fused Silica Ceramic Roller Manufacturers, it’s essential to consider several key qualities to ensure you receive the highest-quality products and services.

1. Experience and Expertise: Look for manufacturers with a proven track record and extensive experience in producing fused silica ceramic rollers. Companies like Kamroller Special Ceramics Co., Ltd., with years of expertise, are more likely to deliver products that meet your specific requirements.

2. Quality Control: Ensure that the manufacturer has robust quality control processes in place. High-quality rollers are critical for industrial applications, and rigorous quality checks are essential to guarantee consistency and reliability.

3. Customization: Every industry has unique needs, so it’s crucial to choose a manufacturer that offers customization options. The ability to tailor the rollers to your specific requirements can significantly enhance their effectiveness in your production processes.

4. Timely Delivery: Efficiency often depends on the timely delivery of components. Reliable manufacturers like Kamroller Special Ceramics Co., Ltd. understand the importance of delivering products on schedule to minimize disruptions in your operations.

5. Technical Support: Manufacturers should offer technical support and assistance, especially during the installation and maintenance of their products. This ensures that you get the most out of your fused silica ceramic rollers.

Boosting Production with Fused Silica Ceramic Roller Manufacturers

Fused silica ceramic rollers have a direct impact on production efficiency. By incorporating these high-performance components into various industrial processes, manufacturers can significantly boost their production rates while maintaining product quality.

In glass manufacturing, for instance, fused silica ceramic rollers are used in tempering furnaces to support glass sheets as they undergo thermal processing. The exceptional thermal stability of these rollers allows for precise control of the heating and cooling process, resulting in high-quality tempered glass products.

Similarly, in the steel industry, fused silica ceramic rollers are employed in continuous casting applications. These rollers provide a stable surface for molten steel to solidify, ensuring consistent product dimensions and reducing the need for costly post-processing.

How Fused Silica Ceramic Roller Manufacturers Cater to Diverse Industries

Fused silica ceramic rollers are versatile components that find applications in diverse industries beyond glass and steel manufacturing. They are also used in semiconductor and photovoltaic manufacturing, where precision and reliability are paramount.

In semiconductor fabrication, these rollers are utilized in diffusion furnaces and chemical vapor deposition (CVD) processes. Their exceptional purity and resistance to contamination make them ideal for handling sensitive semiconductor wafers, ensuring the integrity of the final products.

Additionally, fused silica ceramic rollers have applications in the solar industry, particularly in the production of photovoltaic cells. They are used in high-temperature processes like sintering and firing, where their thermal stability and dimensional accuracy contribute to the efficiency and reliability of solar cell production.

Innovations in Fused Silica Ceramic Roller Manufacturing

The field of fused silica ceramic roller manufacturing is not static; it continuously evolves to meet the changing needs of industries. Innovations in materials and production processes have opened up new possibilities for improving industrial efficiency:

1. Advanced Materials — Fused Silica Ceramic Roller Manufacturers

Manufacturers like Kamroller are harnessing advanced materials and formulations to enhance the performance of fused silica ceramic rollers. These innovations result in rollers with improved thermal conductivity and durability, ultimately leading to more efficient processes.

2. Surface Treatments — Fused Silica Ceramic Roller Manufacturers

Surface treatments, such as coatings and finishes, can further enhance the properties of fused silica ceramic rollers. These treatments can reduce friction, prevent surface contamination, and improve wear resistance, contributing to a longer roller lifespan and reduced maintenance needs.

3. Precision Manufacturing — Fused Silica Ceramic Roller Manufacturers

Advancements in manufacturing techniques, including computer-controlled machining and 3D printing, enable the production of fused silica ceramic rollers with tighter tolerances and more intricate designs. This precision leads to better performance and efficiency in industrial applications.

Conclusion: Elevate Your Production Line with Fused Silica Ceramic Roller Manufacturers

In conclusion, fused silica ceramic rollers are invaluable components that significantly improve industrial efficiency in various sectors. When choosing a manufacturer for these critical components, businesses must carefully consider factors like quality, customization, technical expertise, production capacity, and sustainability. Fused Silica Ceramic Roller Manufacturers like Kamroller Special Ceramics Co., Ltd. excel in these areas, making them a top choice for companies seeking to elevate their production processes.

Moreover, ongoing innovations in fused silica ceramic roller manufacturing continue to push the boundaries of what is possible in terms of industrial efficiency. Advanced materials, surface treatments, and precision manufacturing techniques are all contributing to the evolution of these rollers, allowing businesses to achieve even greater levels of productivity and performance.

In the fast-paced world of industrial manufacturing, the choice of fused silica ceramic roller manufacturers can make a significant difference. By partnering with a reputable and innovative manufacturer like Kamroller, businesses can look forward to improved efficiency, reduced downtime, and enhanced competitiveness in their respective industries.

Post time: 11 月-15-2023