Fused Silica Ceramic Roller

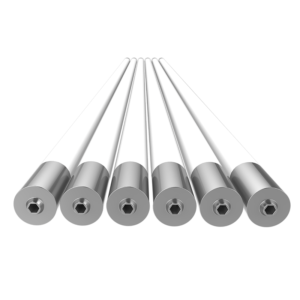

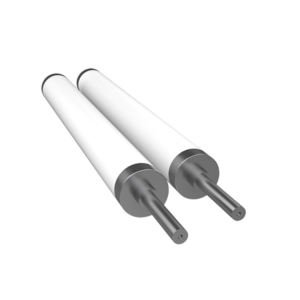

Introducing our Fused Silica Ceramic Roller, a high-performance tool designed for exceptional heat resistance and precise material handling in various industrial applications. Crafted with precision and utilizing advanced fused silica ceramic materials, this roller offers superior durability, thermal stability, and reliability.

The Fused Ceramic Roller is engineered to withstand extreme temperatures. This makes it ideal for use in high-temperature processes such as glass manufacturing, and continuous production lines. Its exceptional heat resistance ensures reliable performance and longevity, even in the most demanding operating conditions.

With its smooth and non-porous surface, the Fused Ceramic Roller minimizes material adhesion and sticking, facilitating the smooth and consistent material transfer. This feature is particularly beneficial in applications where precise material handling and uniformity are crucial. Its inert nature ensures compatibility with a wide range of materials and fluids, making it a versatile tool across various industries.

The precise dimensions and high dimensional stability of the Roller enable accurate and reliable material transport. Its excellent wear resistance minimizes surface deterioration, ensuring consistent and reliable performance over an extended service life. This reduces downtime and maintenance costs, optimizing productivity and efficiency. Moreover, the Fused Roller offers exceptional chemical resistance. This makes it suitable for use in corrosive or chemically aggressive environments.

Sizes Range: Fused Silica Ceramic Roller

Diameter: 20mm-200mm

Length: 1000mm-5000mm

Usage: Fused Silica Ceramic Roller

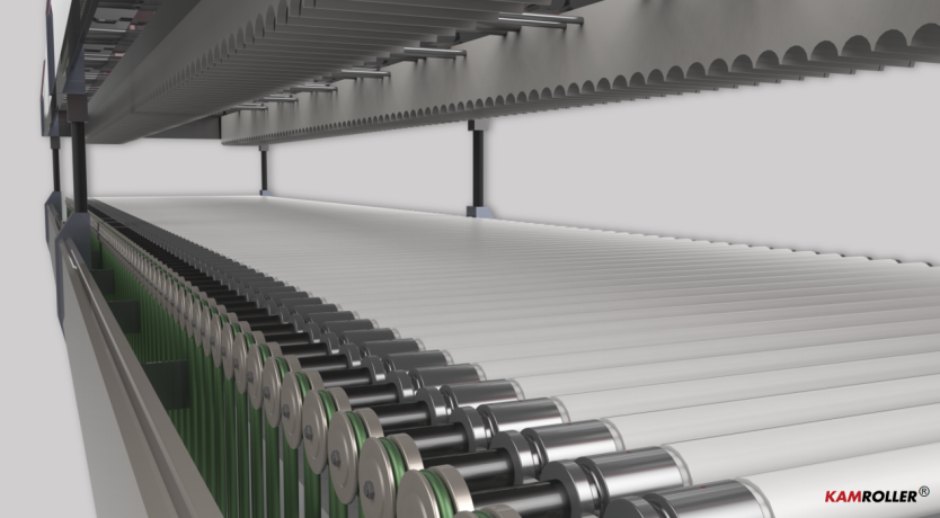

The Fused Silica Roller offers a wide range of applications in various industrial processes where precise material handling and thermal stability are essential. In glass manufacturing, it plays a critical role in the transportation of glass sheets, ensuring smooth and uniform movement throughout the production line. The Fused Silica Roller is also valuable in metal casting processes, where it facilitates the controlled transfer of molten metal, ensuring consistent and accurate casting. Additionally, in continuous production lines, such as conveyor systems, it provides reliable material transport, and ensuring precise positioning

Our Factory Image:

Kamroller Rollers On the Glass Tempering Furnace:

Packing Detail:

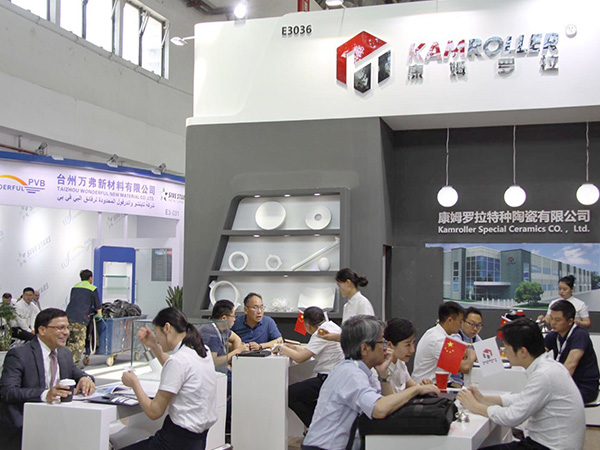

Kamroller At The Exhibition:

ISO Certificate:

- SiO₂ Purity(wt%)—≥99.7

- Bulk Density(g/cm³)—≥1.96

- Apparent Porosity(%)—≤10

- Compressive Strength(Rt)(Mpa)—≥60

- Bending Strength(FIT)(1100℃X0.5h)(Mpa)—≥28

- Thermal Expansion(X10ˉ6 /℃) ( RT-1000℃)—≤0.5

- Dimensional Tolerance(mm)—±0.05