Glass manufacturing requires precision and durability. Smooth transportation of glass sheets through the furnace is essential for ensuring high-quality products. Fused Silica Quartz Rollers have emerged as a reliable solution for glass manufacturers, addressing the pressing needs and challenges faced in the industry.

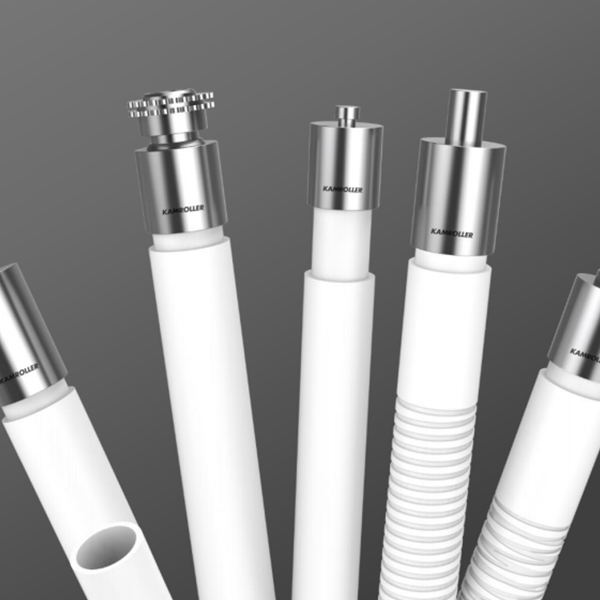

Kamroller Special Ceramics Co., Ltd., a trusted name in the field, has introduced these high-performance rollers that have already proven their mettle by enduring four furnace cycles. In this blog, we’ll explore the needs and challenges of glass manufacturers and how Fused Silica Quartz Roller for Furnance offers a solution that paves the way for smoother, controlled, and efficient glass production.

The Challenges in Glass Manufacturing: Fused Silica Quartz Roller for Furnace

1. Precision and Durability: Glass manufacturing is a delicate dance of precision. The glass sheets must be transported smoothly and without imperfections through the furnace to ensure the final product meets stringent quality standards. Traditional rollers often fall short, causing defects in the glass sheets. Moreover, the extreme temperatures within the furnace can wreak havoc on rollers, leading to frequent replacements, and thereby increasing downtime and maintenance costs.

2. Control and Consistency: Maintaining control over the glass sheets’ movement is crucial. Any variation can lead to defects, resulting in wastage and increased production costs. Traditional rollers may not provide the level of consistency required, leading to quality issues and inefficiencies.

3. Reducing Friction and Heat: Glass manufacturers constantly battle the effects of heat and friction during production. Excessive heat can cause roller deformations and shorten their lifespan. Reducing friction is equally important as it minimizes the risk of glass marking and surface imperfections.

Fused Silica Quartz Roller for Furnace: A Reliable Solution

1. Proven Durability: Kamroller Special Ceramics Co., Ltd. has introduced Fused Silica Quartz Rollers that have already withstood four furnace cycles. This remarkable durability reduces the need for frequent replacements, lowering downtime and maintenance costs significantly. Glass manufacturers can count on these rollers to endure the high-temperature environment, ensuring a smooth and continuous production process.

2. Smooth and Controlled Transportation: Fused Silica Quartz Rollers provide glass manufacturers with precise dimensions and a smooth surface finish. This is a game-changer in the industry as it guarantees a stable and frictionless platform for glass sheet transportation. With these rollers in place, glass manufacturers can ensure that each sheet moves through the furnace with impeccable precision and control, reducing the risk of defects and wastage.

3. Long-Term Cost Savings: The durability of Fused Silica Quartz Rollers translates to significant long-term cost savings for glass manufacturers. By minimizing the need for frequent replacements and reducing maintenance expenses, manufacturers can reinvest their resources in improving other aspects of their production process, leading to a more efficient and cost-effective operation.

4. Quality Assurance: With Fused Silica Quartz Rollers, glass manufacturers can enhance the quality of their products. The precision and control provided by these rollers ensure that glass sheets come out of the furnace with minimal defects. This not only reduces waste but also enhances the reputation of the manufacturer for producing high-quality glass products.

5. Reduced Heat and Friction: These rollers are designed to withstand extreme temperatures and reduce friction. By doing so, they extend their lifespan and minimize the risk of deformation due to excessive heat. The reduction in friction also safeguards against glass marking, contributing to a pristine final product.

Investing in Quality: Fused Silica Quartz Roller for Furnace Applications

Glass manufacturing is a delicate process that relies heavily on temperature control, and the use of rollers in high-temperature environments is indispensable. Fused Silica Quartz Roller for Furnance is the preferred choice for many furnace applications due to its exceptional properties. These rollers are made from fused silica, a high-purity and high-temperature-resistant material, making them ideal for the demanding conditions within a furnace.

1. The Raw Material: Fused Silica

The journey of a Fused Silica Quartz Roller begins with the selection of the raw material – fused silica. Fused silica is made by melting pure silica (SiO2) at extremely high temperatures and then cooling it rapidly to create an amorphous, glassy structure. This unique structure gives fused silica its excellent thermal properties, making it an ideal choice for applications involving extreme heat.

2. Precision Manufacturing

Kamroller Special Ceramics Co., Ltd. takes great care in the manufacturing process of these rollers. The precision required in crafting Fused Silica Quartz Rollers is paramount. The rollers are shaped, polished, and finished to exacting specifications, ensuring they can withstand the rigors of the glass manufacturing environment.

Why Fused Silica Quartz Roller for Furnace is a Must-Have in Glass Production

The significance of fused silica quartz rollers in glass production cannot be overstated. These rollers play a pivotal role in maintaining the quality and efficiency of the manufacturing process. Here’s why they are a must-have:

1. High Thermal Stability: Fused silica quartz rollers can withstand extreme temperatures, making them ideal for the glass manufacturing environment, where temperatures can exceed 1000°C.

2. Low Thermal Expansion: These rollers have minimal thermal expansion, ensuring that they maintain their shape and dimensions even under intense heat, which is critical for consistent glass production.

3. Purity: The purity of fused silica quartz minimizes the risk of contamination in the glass products, ensuring that the final output meets strict quality standards.

4. Durability: Through meticulous manufacturing and heat treatment, these rollers exhibit exceptional durability, leading to extended service life and reduced downtime.

5. Efficiency: The smooth surface of fused silica quartz rollers ensures the glass sheets or products move effortlessly through the furnace, enhancing production efficiency.

Investing in quality fused silica quartz rollers, such as those offered by Kamroller Special Ceramics Co., Ltd., is a smart choice for glass manufacturers. These rollers contribute to a seamless and efficient production process, ultimately leading to high-quality glass products that meet the most demanding industry standards.

Conclusion

Fused Silica Quartz Roller for Furnance from Kamroller Special Ceramics Co., Ltd. represents a breakthrough for the glass manufacturing industry. These rollers address the pressing needs and challenges faced by manufacturers by providing proven durability, precision, and control over the transportation of glass sheets.

The reduction in maintenance costs, increased efficiency, and improved product quality make them an invaluable addition to any glass production facility. As the industry continues to evolve, these rollers are likely to play an increasingly pivotal role in shaping the future of glass manufacturing.

Post time: 10 月-24-2023