North Glass Furnace Used Kamroller Fused Silica Rollers

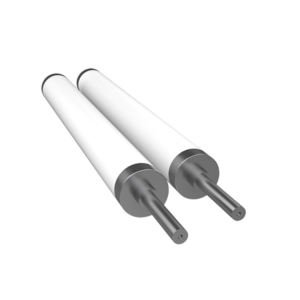

| Product Name | Fused Silica Ceramic Roller | SiO₂ Purity | ≥99.7% |

| Brand | Kamroller | Color | White |

| ThermalExpansion (X10ˉ6/℃) ( RT-1000℃) | ≤0.5 | Place of Product | Jiangsu Province, China |

| Dimensional Tolerance (mm) | ±0.05 | Modes of packing | Packed in plywood cases |

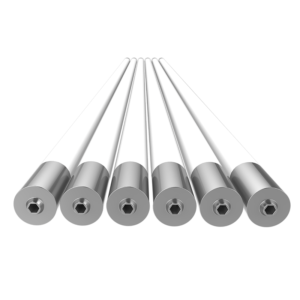

| Size | φ25-120mm, length as requested | After sale service | 24 hours, Monday-Sunday |

Each Fused Silica Roller has been crafted from high-quality fused silica material, renowned for its outstanding thermal stability, low thermal expansion, and superior resistance to thermal shock. These properties make them ideal for withstanding the extreme temperatures and demanding conditions of glass production.

These rollers have been used in furnaces for four cycles, demonstrating their reliability and durability. They have successfully supported and transported glass sheets or panels within the furnace, ensuring smooth and controlled movement without causing surface defects or damage.

With their precise dimensions and smooth surface finish, the Fused Silica Rollers provide a stable and frictionless platform for transporting glass. Their exceptional thermal stability allows them to maintain their structural integrity and dimensional stability even at high temperatures, ensuring consistent and reliable performance throughout their usage cycles.

Usage: North Glass Furnace Used Kamroller Fused Silica Rollers

The North Glass Furnace Used Silica Rollers are an excellent choice for glass manufacturers seeking reliable and high-performance rollers. These rollers, already utilized in North Glass furnaces for four cycles, offer proven durability and performance. Using the Fused Rollers, glass manufacturers can ensure smooth and controlled transportation of glass sheets. With their precise dimensions and smooth surface finish, these rollers provide a stable and frictionless platform.

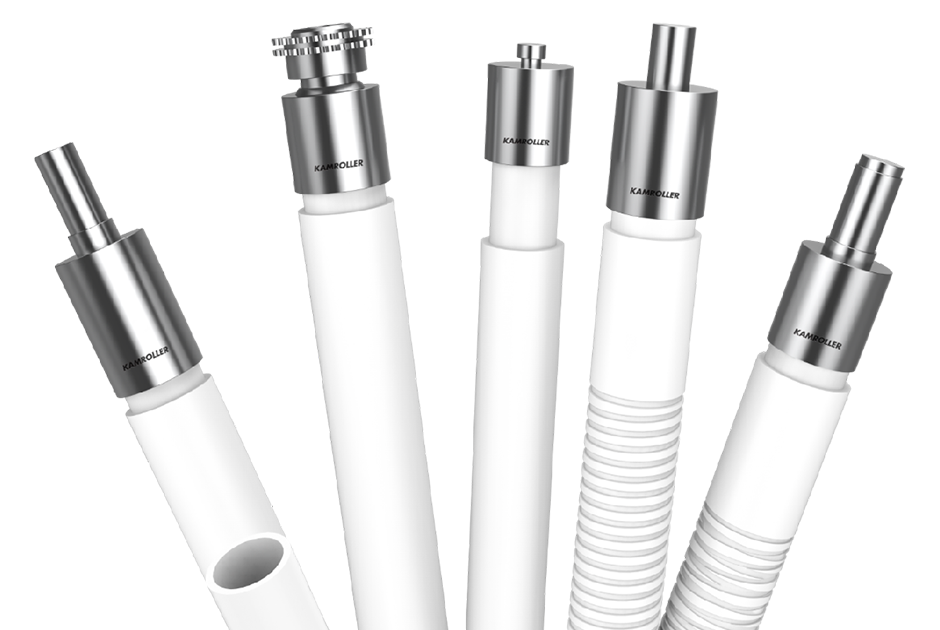

Check our new product Kamroller Fused Silica Ceramic Roller For Glass Tempering Furnace

|

Fuse Silica Roller Specifications |

|

| SiO2 (wt%) Purity | ≥99.6 |

| Color | White |

| Max Using Temperature | 1250℃ |

| Density (g/cm³) | ≥1.8-2.1 |

| Apparent Porosity (%) | 5-20 |

| Compressive Strength (Rt) (Mpa) | ≥60 |

| Bending Strength (FIT) (1100℃X0.5h) (Mpa) | 20-70 |

| Thermal Expansion (X10-6/℃) (RT-1000℃) | 0.54×10-6 |

| Thermal Conductivity Coefficient (w/m·s·k) | ≤0.5 |

| Thermal Shock Resistance | 1200℃-20℃

Thermal Shock > 20 Times |

| Moh’s Hardness | 7 |