Fused Silica Ceramic Molds

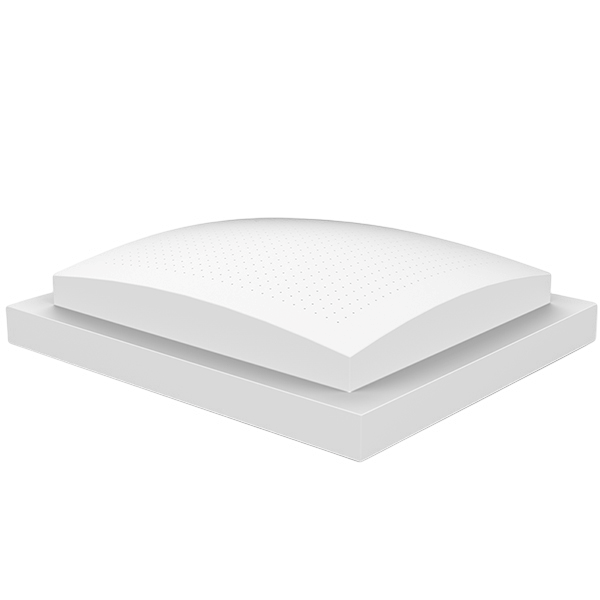

Introducing Fused Silica Ceramic Molds, a high-quality solution designed for precision molding and casting applications. These molds are made from fused silica ceramic material. They are renowned for its exceptional heat resistance, dimensional stability, and smooth surface finish.

Fused Silica Ceramic Molds are widely used in industries such as glass manufacturing, jewelry making, and metal casting. They are specifically engineered to withstand high temperatures and ensure accurate replication of intricate details in the molded or cast objects.

In glass manufacturing, Fused Molds play a crucial role in shaping and forming glassware, decorative items, and precision components. They provide the necessary support and structure for molten glass. This allows it to cool and solidify into the desired shape with precise detail and smooth finishes.

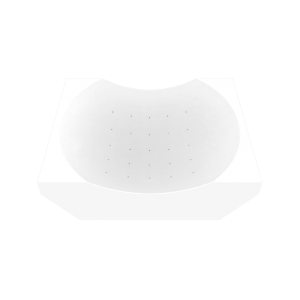

In jewelry making, these molds enable the creation of intricate and delicate jewelry pieces. They are utilized for casting precious metals, such as gold, silver, and platinum. This also ensures a precise replication of intricate designs and maintaining the highest level of craftsmanship.

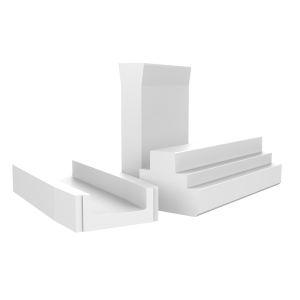

Furthermore, Fused Ceramic Molds are utilized in metal casting processes. They are commonly employed in industries such as automotive, aerospace, and industrial manufacturing, where intricate metal components are produced through casting. These molds facilitate the precise replication of complex geometries, resulting in high-quality metal parts with exceptional accuracy and dimensional consistency.

Usage: Fused Silica Ceramic Molds

Fused Silica Molds are extensively used in various industries for precision molding and casting applications. These molds are designed to withstand high temperatures and ensure accurate replication of intricate details in the molded or cast objects. They find wide usage in industries such as glass manufacturing, jewelry making, and metal casting. In glass manufacturing, Silica Ceramic Molds are utilized to shape and form glassware, decorative items, and precision components.

|

Fuse Silica Roller Specifications |

|

| SiO2 (wt%) Purity | ≥99.6 |

| Color | White |

| Max Using Temperature | 1250℃ |

| Density (g/cm³) | ≥1.8-2.1 |

| Apparent Porosity (%) | 5-20 |

| Compressive Strength (Rt) (Mpa) | ≥60 |

| Bending Strength (FIT) (1100℃X0.5h) (Mpa) | 20-70 |

| Thermal Expansion (X10-6/℃) (RT-1000℃) | 0.54×10-6 |

| Thermal Conductivity Coefficient (w/m·s·k) | ≤0.5 |

| Thermal Shock Resistance | 1200℃-20℃

Thermal Shock > 20 Times |

| Moh’s Hardness | 7 |