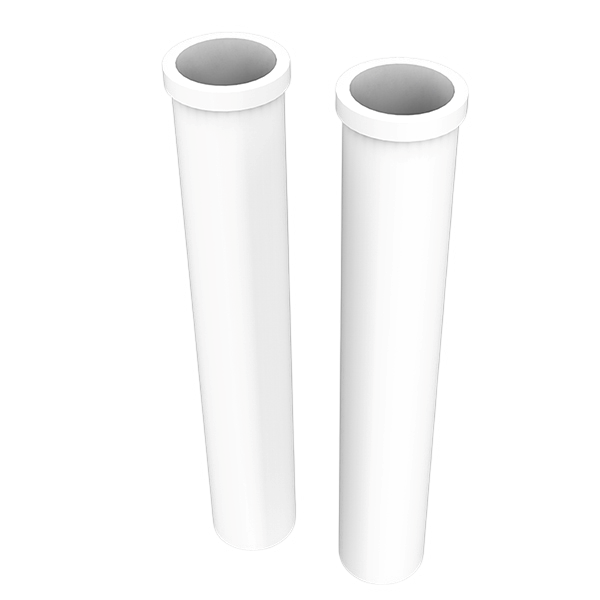

Fused Silica Barrels

Introducing Fused Silica Barrels, a superior solution designed for high-temperature and corrosive environments. These barrels are made from high-purity fused silica, known for its exceptional thermal stability, chemical resistance, and durability.

Fused Silica find extensive usage in industries such as chemical processing, semiconductor manufacturing, and laboratory applications. They serve as critical components in processes that involve the handling, storage, and transportation of corrosive or high-temperature materials. The durability and longevity of Fused Silica Barrels make them a cost-effective choice for industrial applications.

In chemical processing, Barrels are utilized for the safe and efficient containment of corrosive chemicals, acids, and solvents. Their exceptional chemical resistance ensures compatibility with a wide range of substances, preventing contamination and maintaining the integrity of the stored materials.

In semiconductor manufacturing, these barrels are employed for the handling and transportation of high-purity gases, chemicals, and process fluids. They provide a reliable and contamination-free environment, ensuring the integrity of the materials during various stages of semiconductor fabrication. They are used in laboratory settings for the storage and transport of sensitive samples, reagents, and solutions. Their inert nature and resistance to thermal shock also makes them ideal for preserving the integrity of valuable or delicate substances.

Usage: Fused Silica Barrels

Fused Silica Barrels are extensively used in industries that require reliable and durable containment solutions for corrosive or high-temperature materials. These barrels find wide usage in applications such as chemical processing, semiconductor manufacturing, and laboratory settings. In chemical processing, Fused Barrels also provide a safe and reliable means of storing and transporting corrosive chemicals, acids, and solvents. Their exceptional chemical resistance ensures compatibility with a wide range of substances. This however prevents the contamination and maintains the integrity of the stored materials.

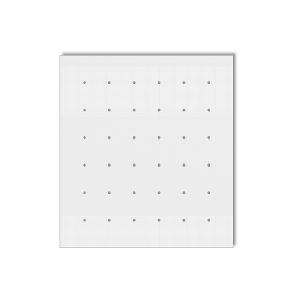

|

Fuse Silica Roller Specifications |

|

| SiO2 (wt%) Purity | ≥99.6 |

| Color | White |

| Max Using Temperature | 1250℃ |

| Density (g/cm³) | ≥1.8-2.1 |

| Apparent Porosity (%) | 5-20 |

| Compressive Strength (Rt) (Mpa) | ≥60 |

| Bending Strength (FIT) (1100℃X0.5h) (Mpa) | 20-70 |

| Thermal Expansion (X10-6/℃) (RT-1000℃) | 0.54×10-6 |

| Thermal Conductivity Coefficient (w/m·s·k) | ≤0.5 |

| Thermal Shock Resistance | 1200℃-20℃

Thermal Shock > 20 Times |

| Moh’s Hardness | 7 |